Precision Engineering Meets Sustainability

As part of the FEA Water Tower Challenge 2025, our team designed and analysed a lightweight, biodegradable water tower, balancing structural efficiency with environmental responsibility through advanced finite element analysis.

Design Challenges

Load Optimization

Maximising load-bearing capacity while minimising material usage through strategic structural design and analysis.

Sustainable Materials

Using biodegradable pasta materials while maintaining structural integrity and performance requirements.

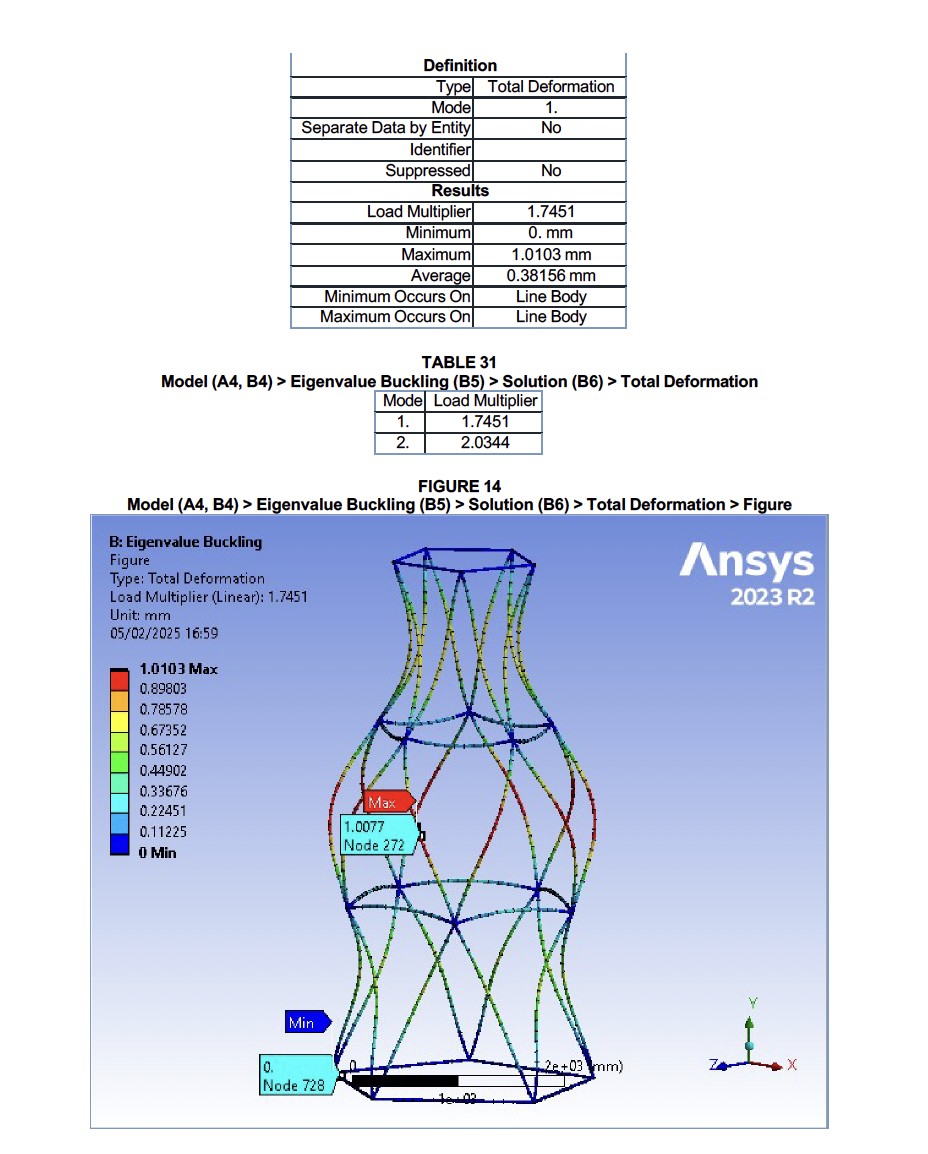

Buckling Prevention

Preventing structural instability and buckling under load through advanced finite element analysis.

FEA-Driven Solution

Using ANSYS, we conducted extensive static and buckling analyses, refining our design through iterative simulations to achieve optimal load-bearing capacity and structural stability.

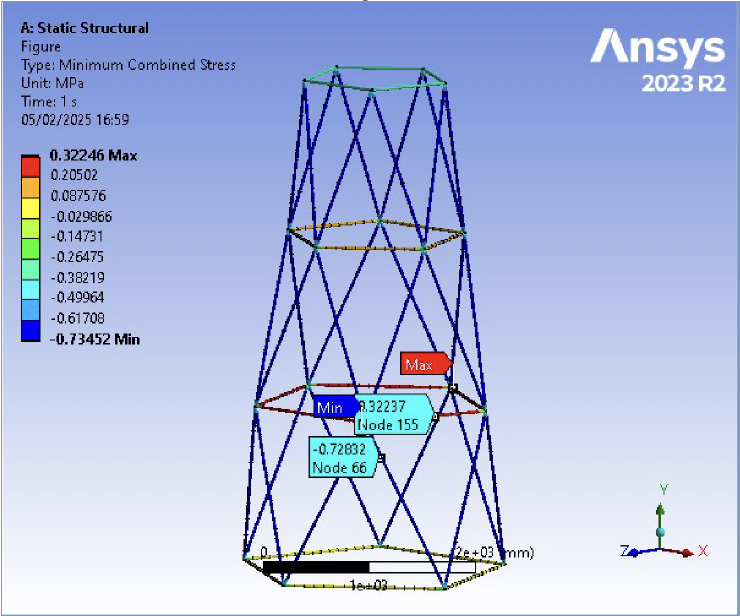

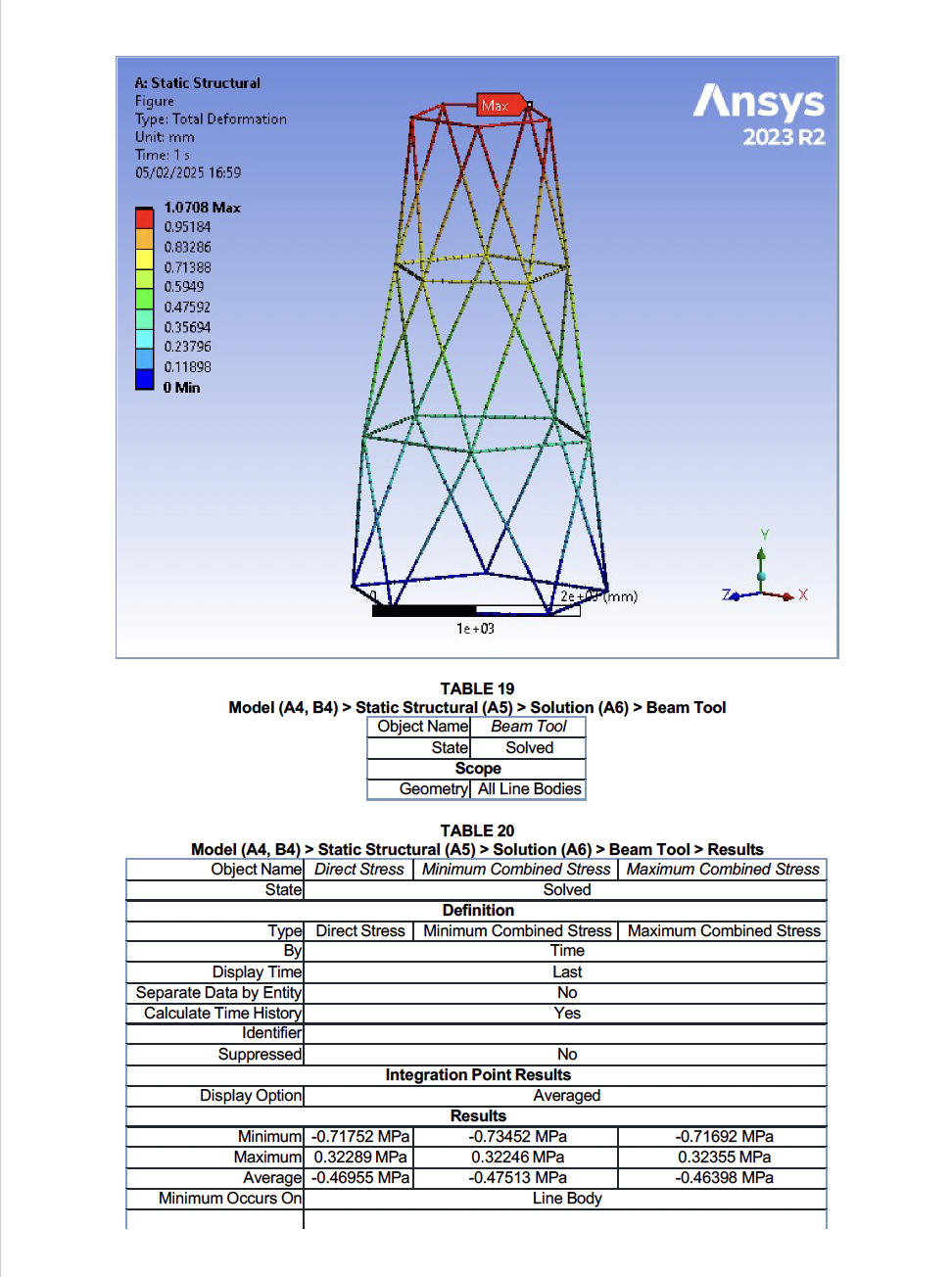

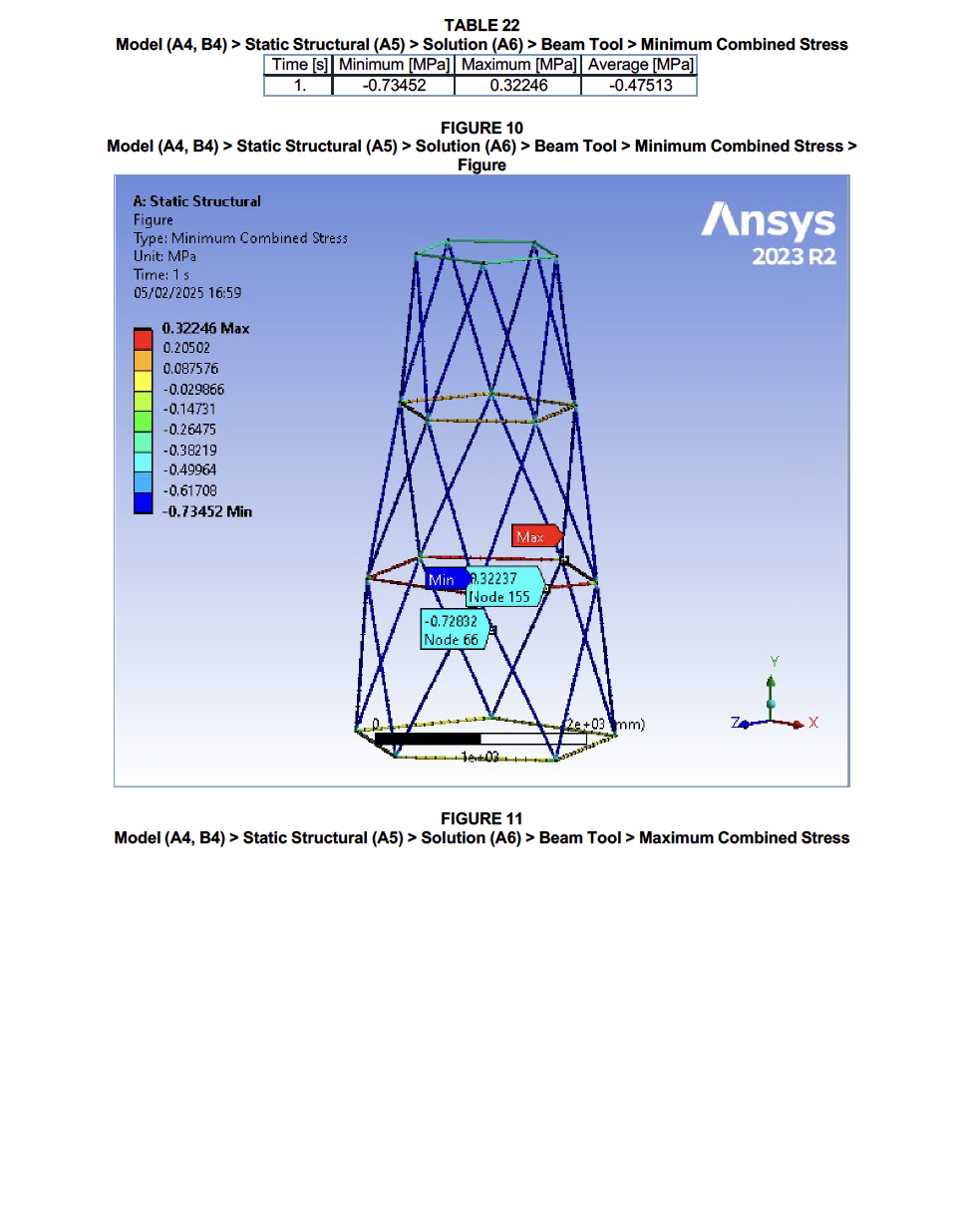

Static Analysis

Comprehensive stress and displacement analysis to optimise material distribution and structural efficiency.

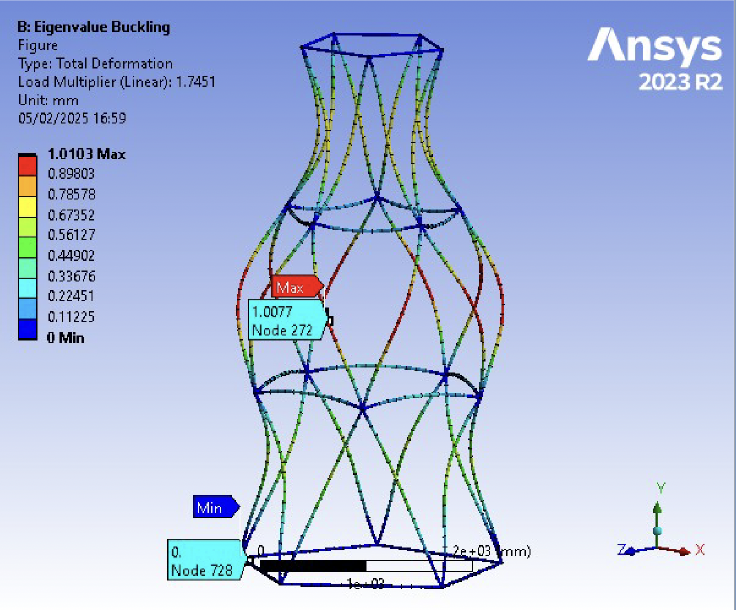

Buckling Analysis

Critical load factor determination and instability prevention through eigenvalue buckling analysis.

Iterative Optimisation

Multiple design iterations guided by FEA results to achieve maximum performance efficiency.

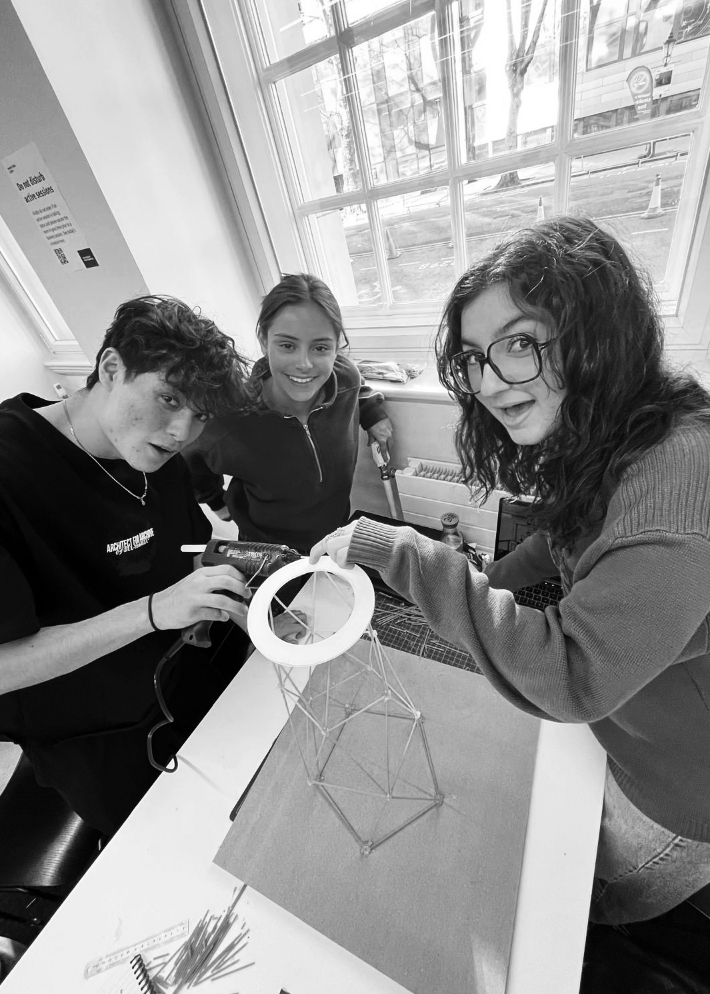

Validation Testing

Physical testing with pasta construction confirming simulation accuracy and design effectiveness.

Key Results

- Maximum load capacity achieved

- Zero buckling failure

- Optimal material distribution

- 93% prediction accuracy

- Sustainable design approach

- 1st place competition finish

Analysis Process

Initial Design

Conceptualising tower geometry and establishing design constraints for biodegradable material properties.

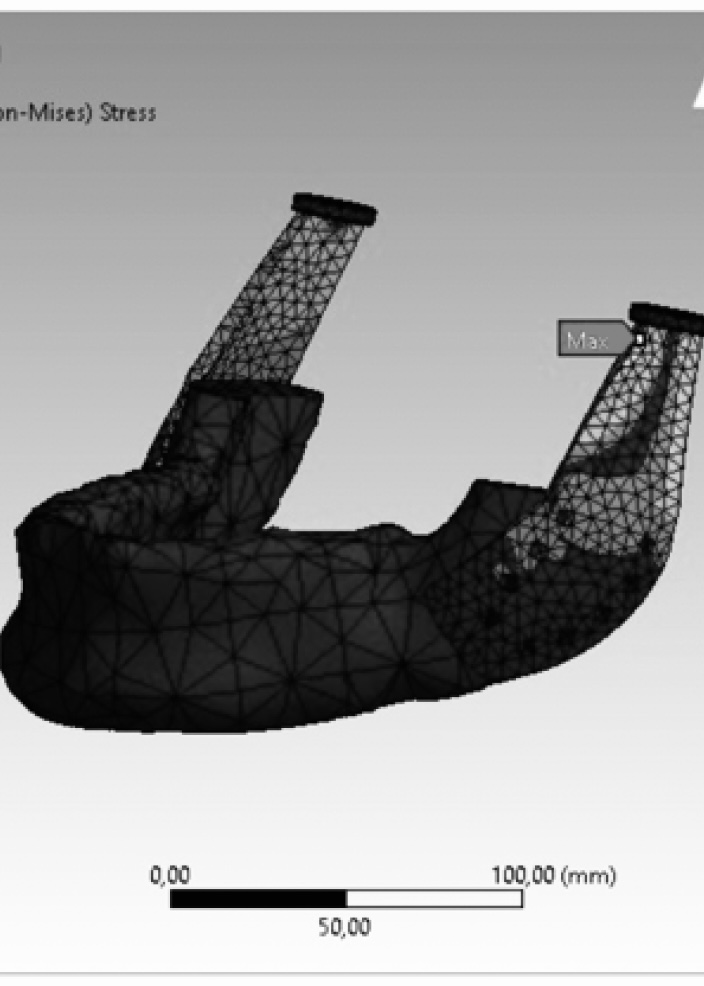

FEA Modeling

Creating detailed ANSYS models with appropriate boundary conditions and material definitions.

Analysis & Optimisation

Running static and buckling analyses, identifying stress concentrations and optimising design geometry.

Physical Validation

Constructing the optimised design with pasta and validating FEA predictions through load testing.

Analysis Documentation

Extract of documentation of our FEA methodology, stress analysis results, and design optimisation process that led to our competition victory.

Championship Results

Our accurate FEA predictions were validated when our pasta tower successfully supported the highest weight in the competition, demonstrating the precision of our structural simulations and securing 1st place.

Competition Victory

First place finish in FEA Water Tower Challenge 2025 among all competing teams

Perfect Prediction

93% accuracy between FEA simulations and physical testing results under load

Sustainable Innovation

Successfully balanced maximum performance with environmentally responsible material use

"This challenge demonstrated how precise finite element analysis can bridge the gap between theoretical design and real-world performance, validating the power of simulation-driven engineering."