Bridging Digital Simulation and Physical Reality

As part of the Thermofluids module in second year, I undertook a two-part design challenge combining aerodynamic design, fluid dynamics, and thermal engineering. The task: to conceptualise a modern vehicle archetype and develop a liquid-cooled thermal management system for its battery.

Engineering Challenges

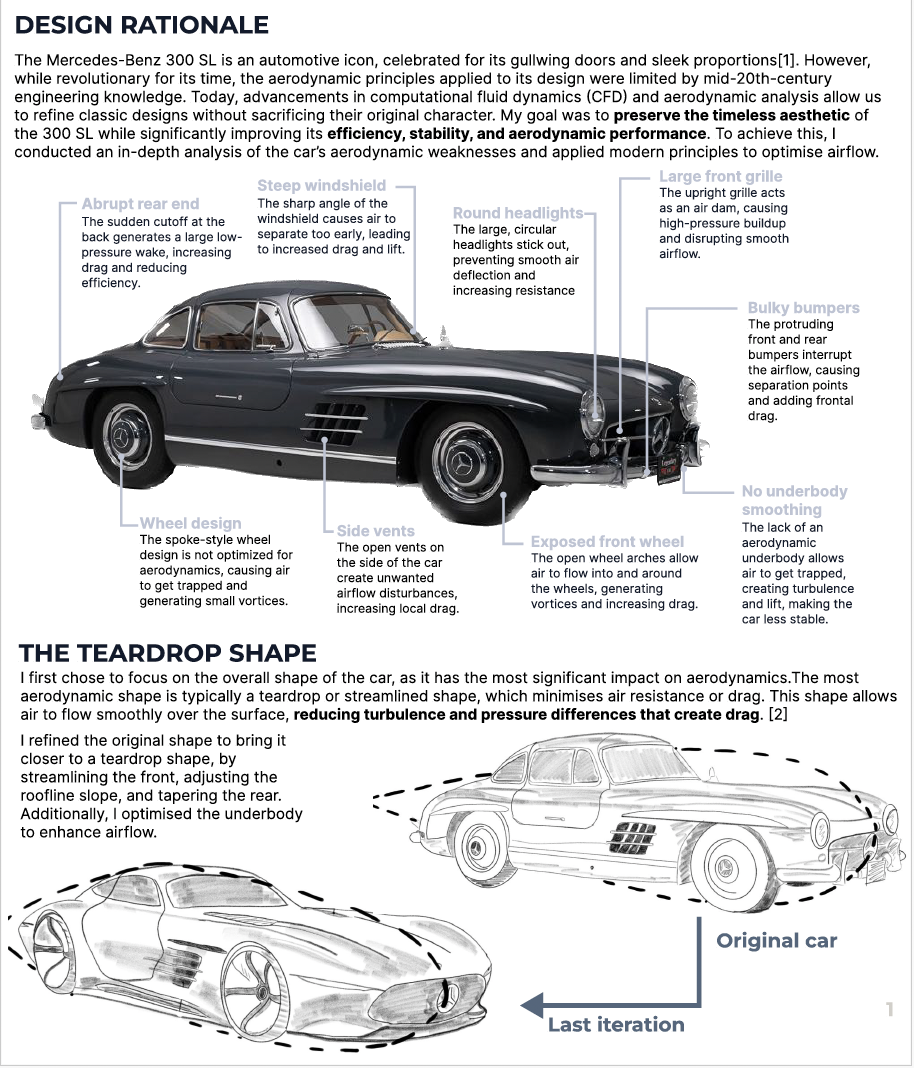

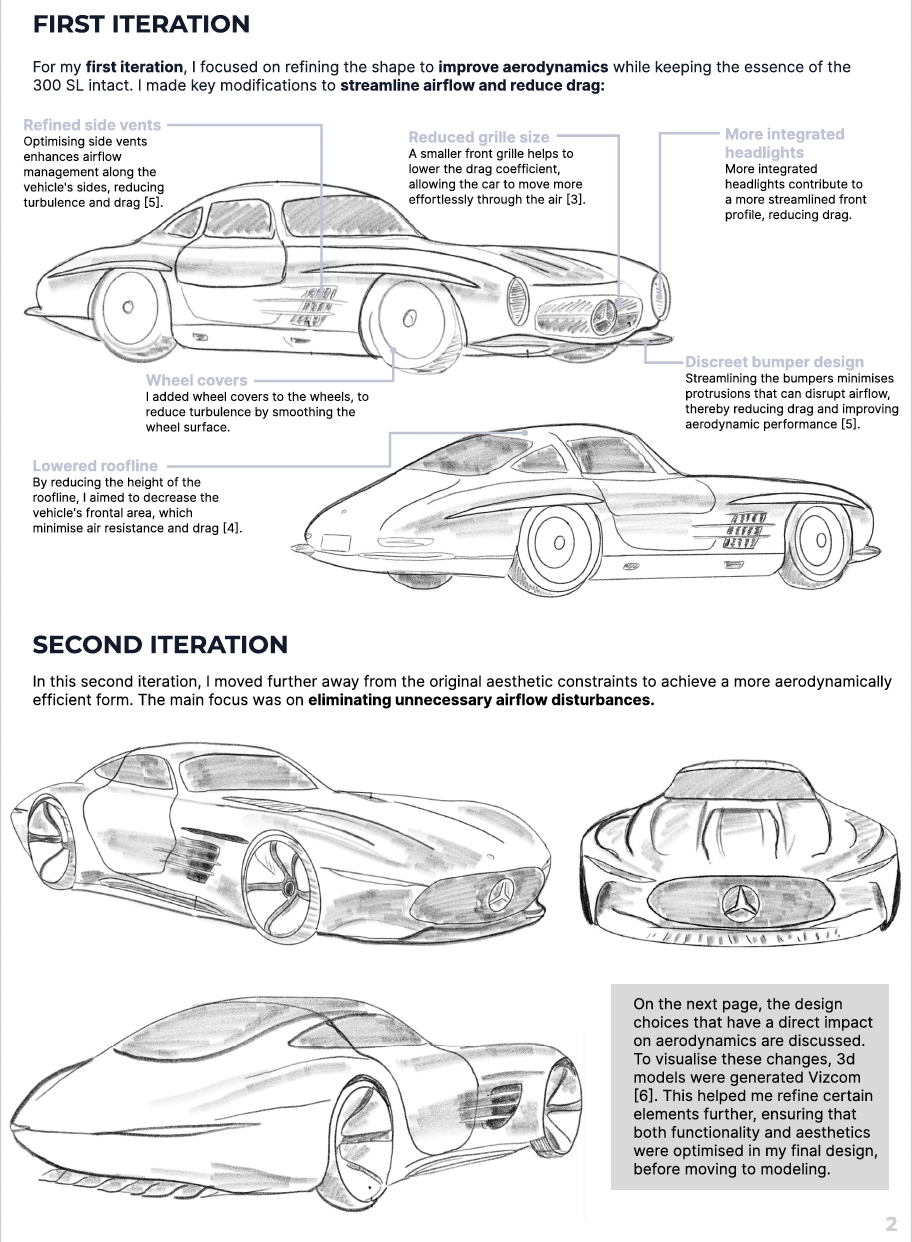

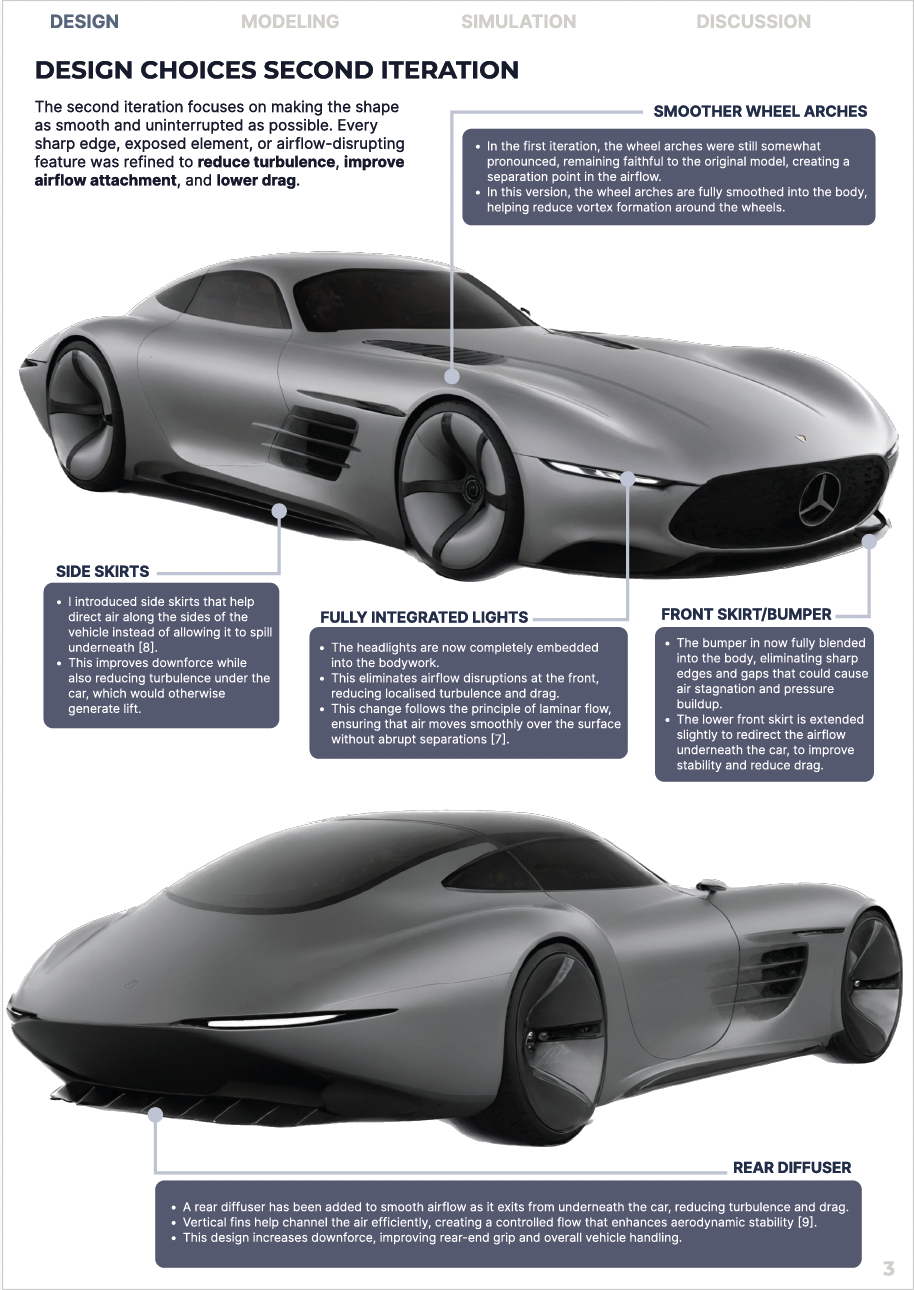

Aerodynamic Optimisation

Redesigning the Mercedes-Benz 300 SL to minimise drag and lift while maintaining aesthetic appeal and structural integrity.

Thermal Management

Developing efficient battery cooling systems with optimal flow velocity, pressure drop, and uniform heat distribution.

Simulation Validation

Bridging the gap between CFD predictions and physical reality through wind tunnel testing and experimental validation.

Engineering Solutions

Using iterative 3D CAD modeling and CFD analysis in ANSYS, I identified and corrected key aerodynamic inefficiencies while developing an advanced thermal management system.

Aerodynamic Redesign

Modern features including diffusers, side skirts, and S-duct to optimise airflow and reduce drag coefficients.

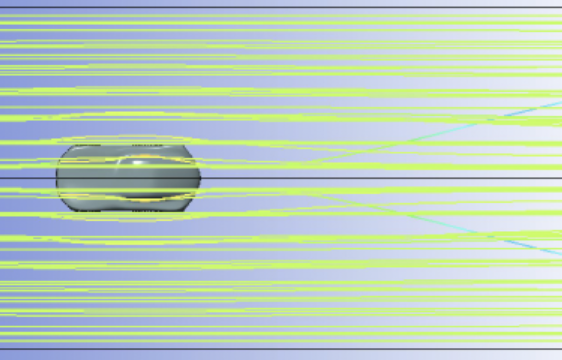

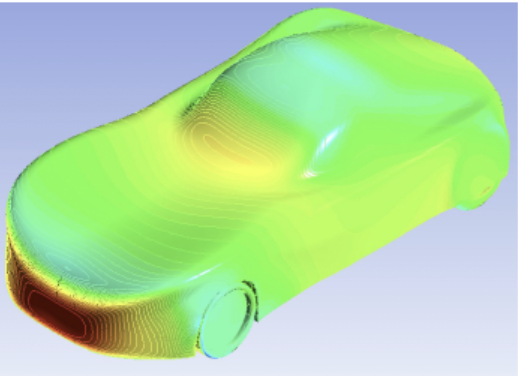

CFD Analysis

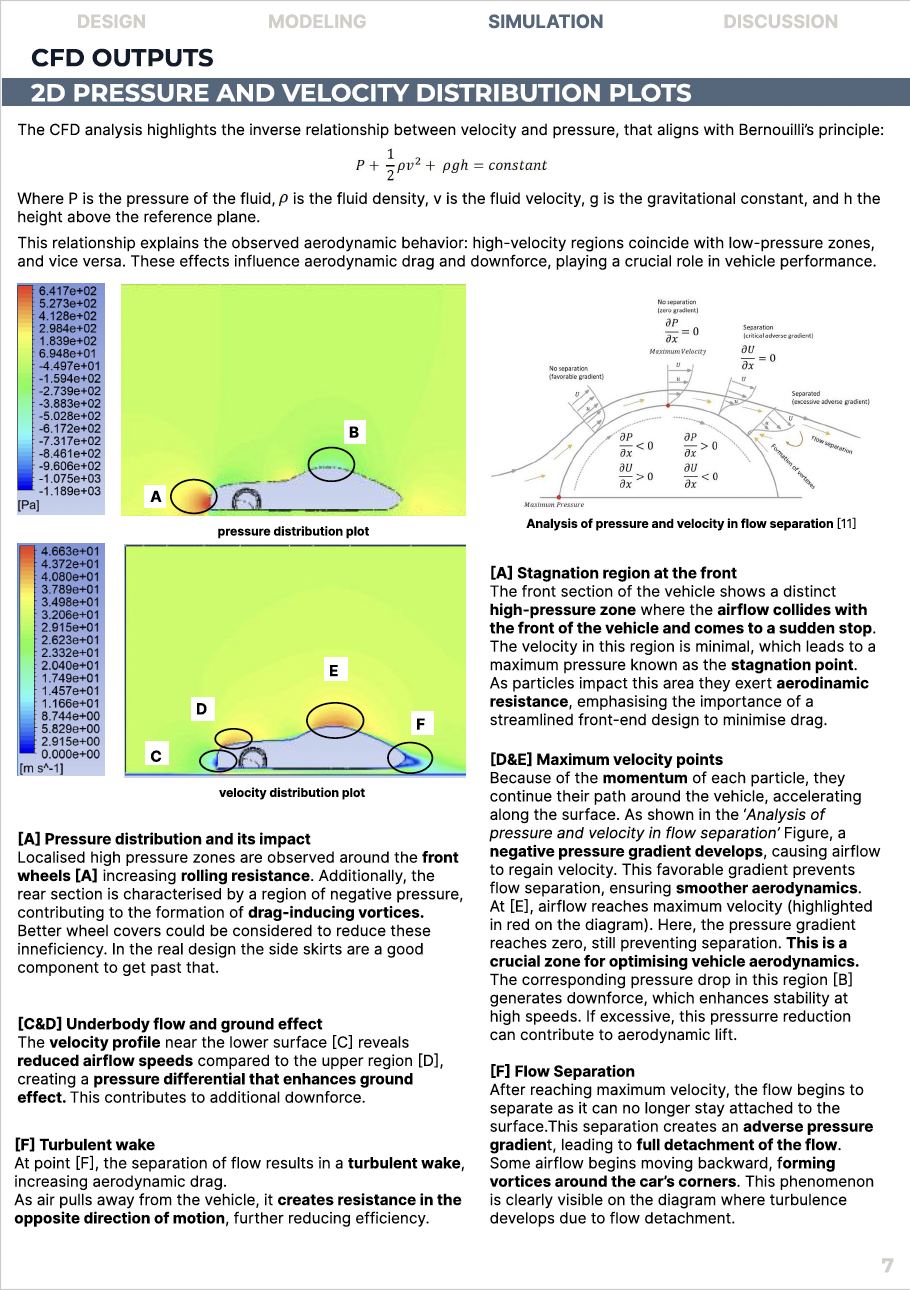

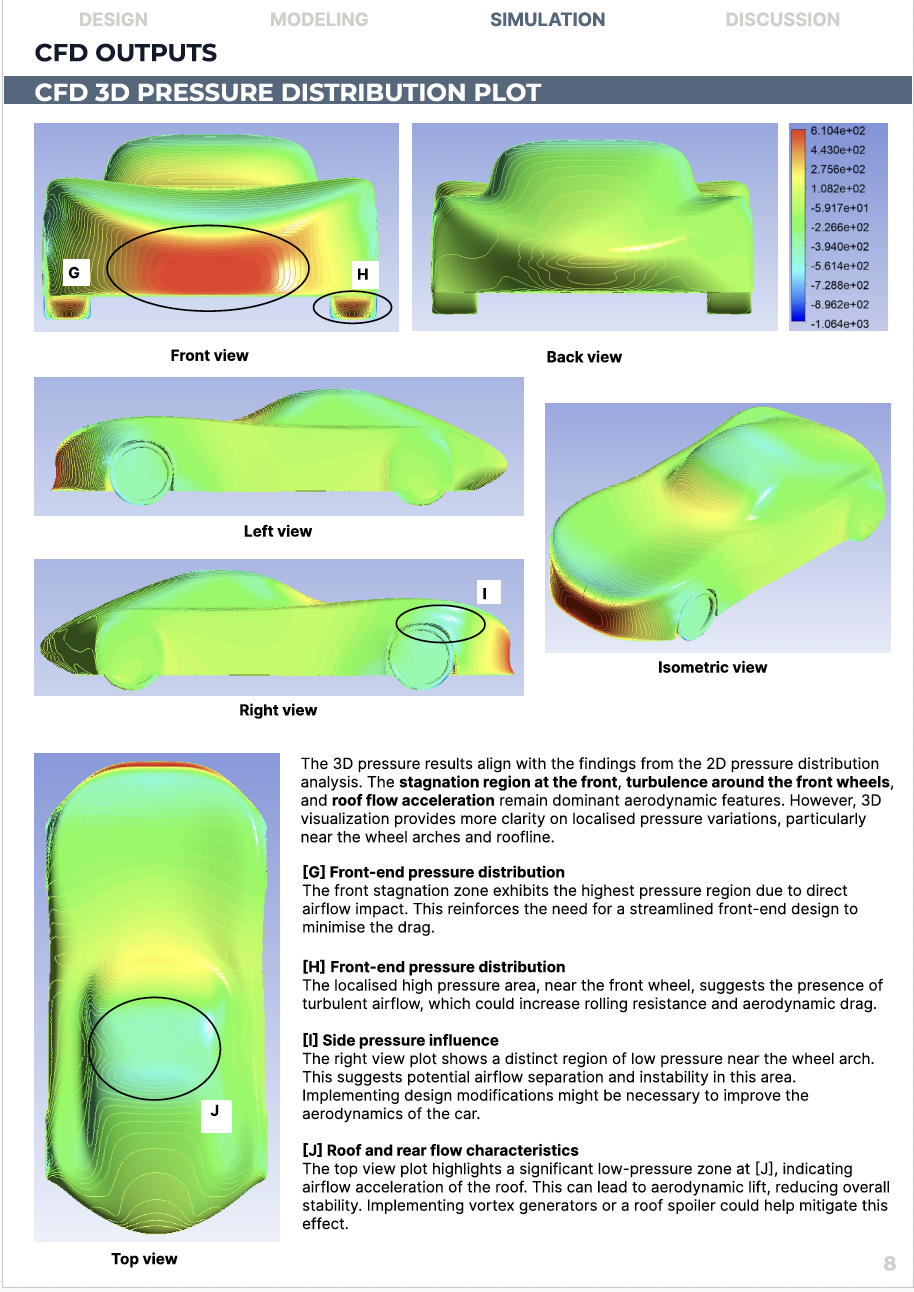

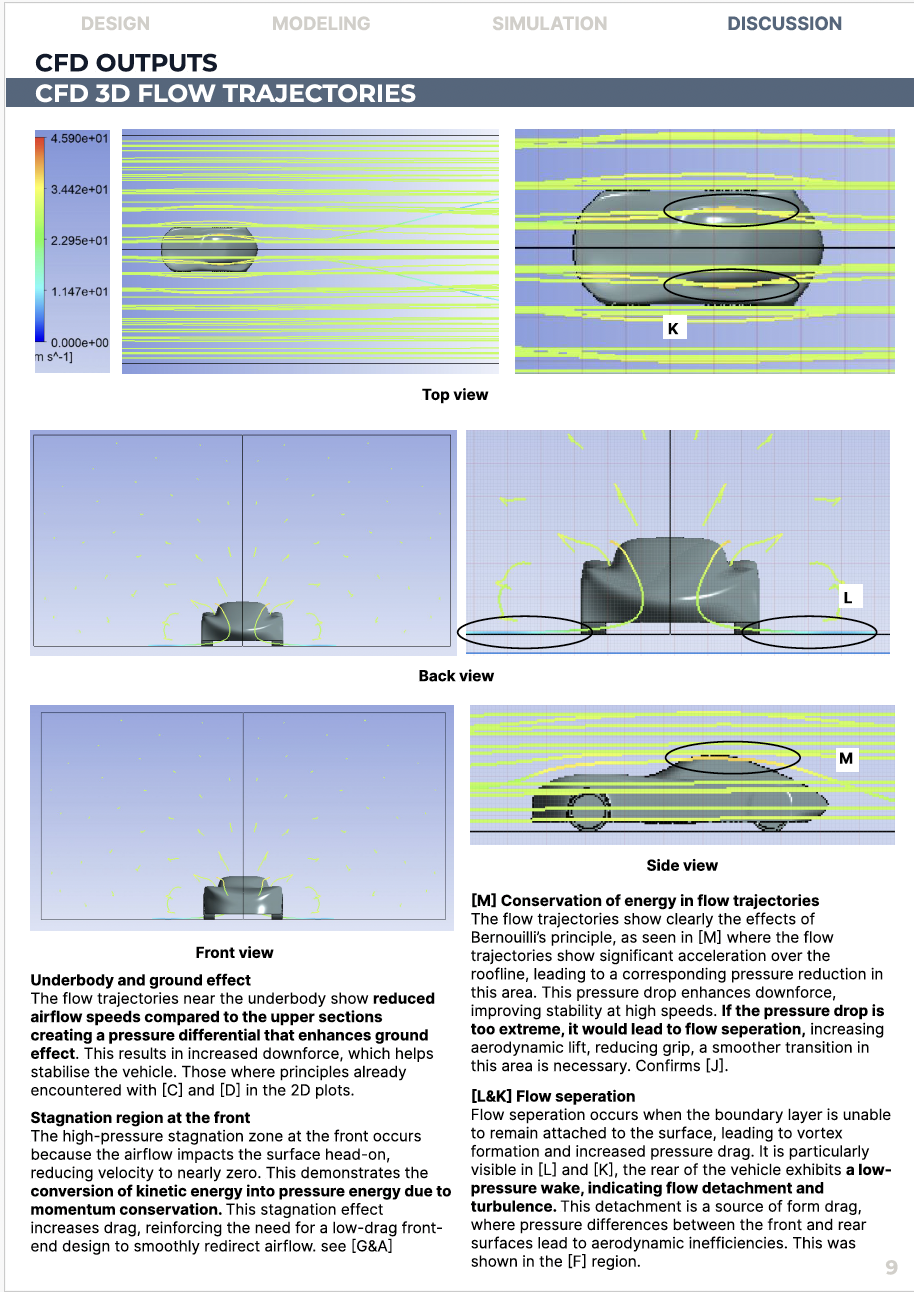

Comprehensive computational fluid dynamics simulations to analyse flow patterns and pressure distributions.

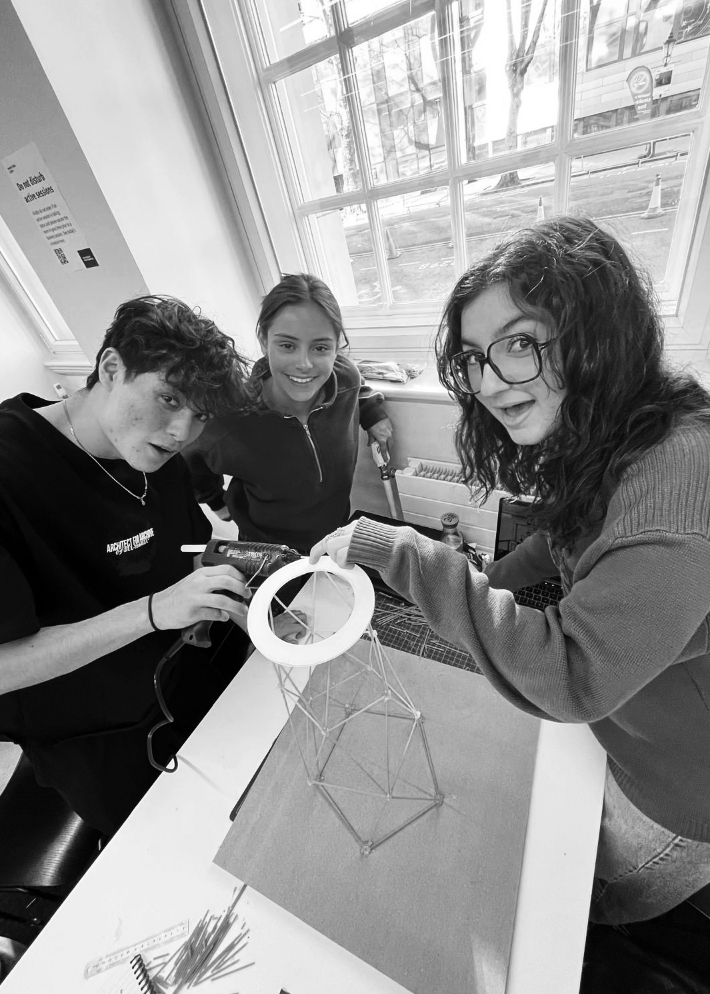

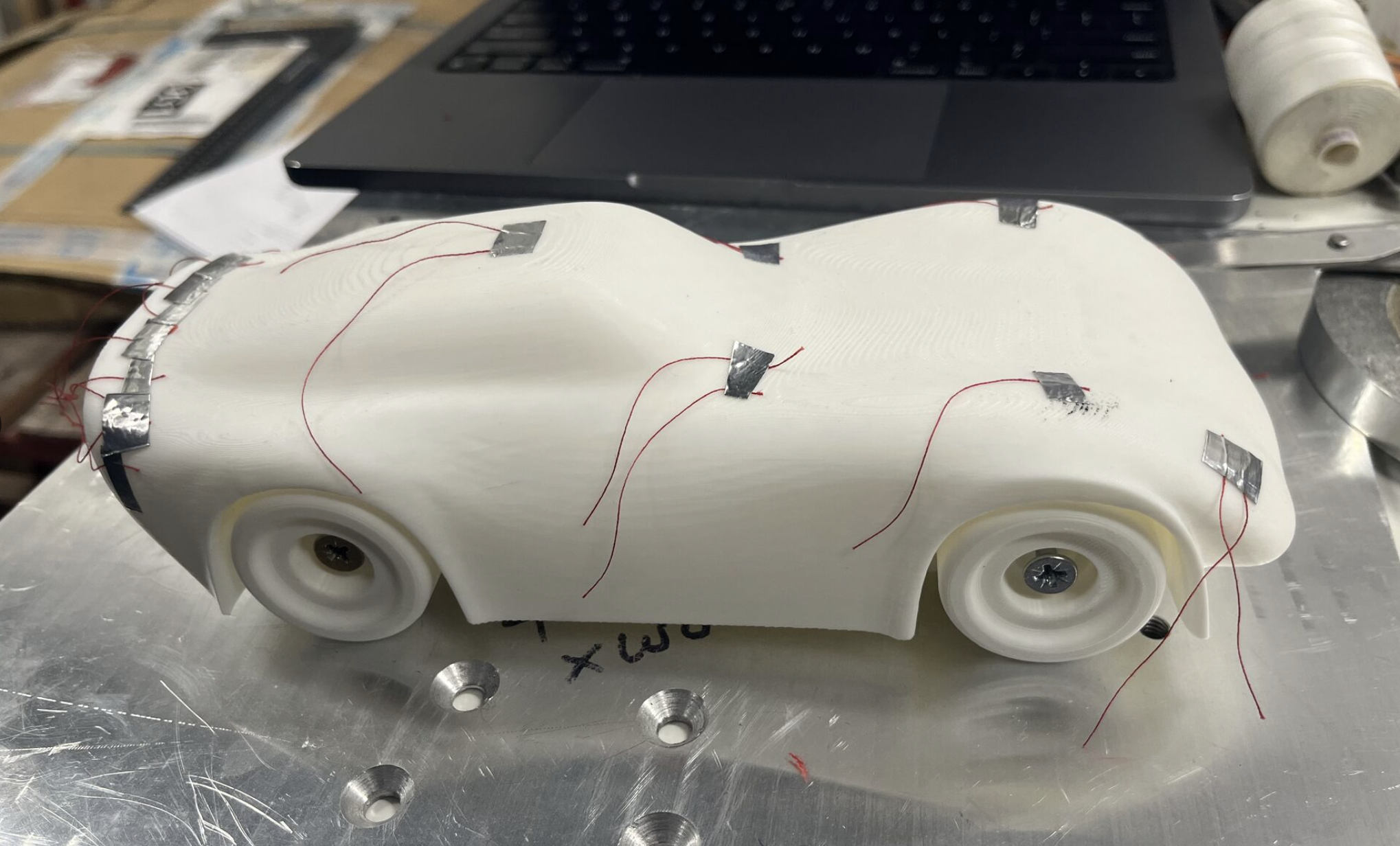

Physical Validation

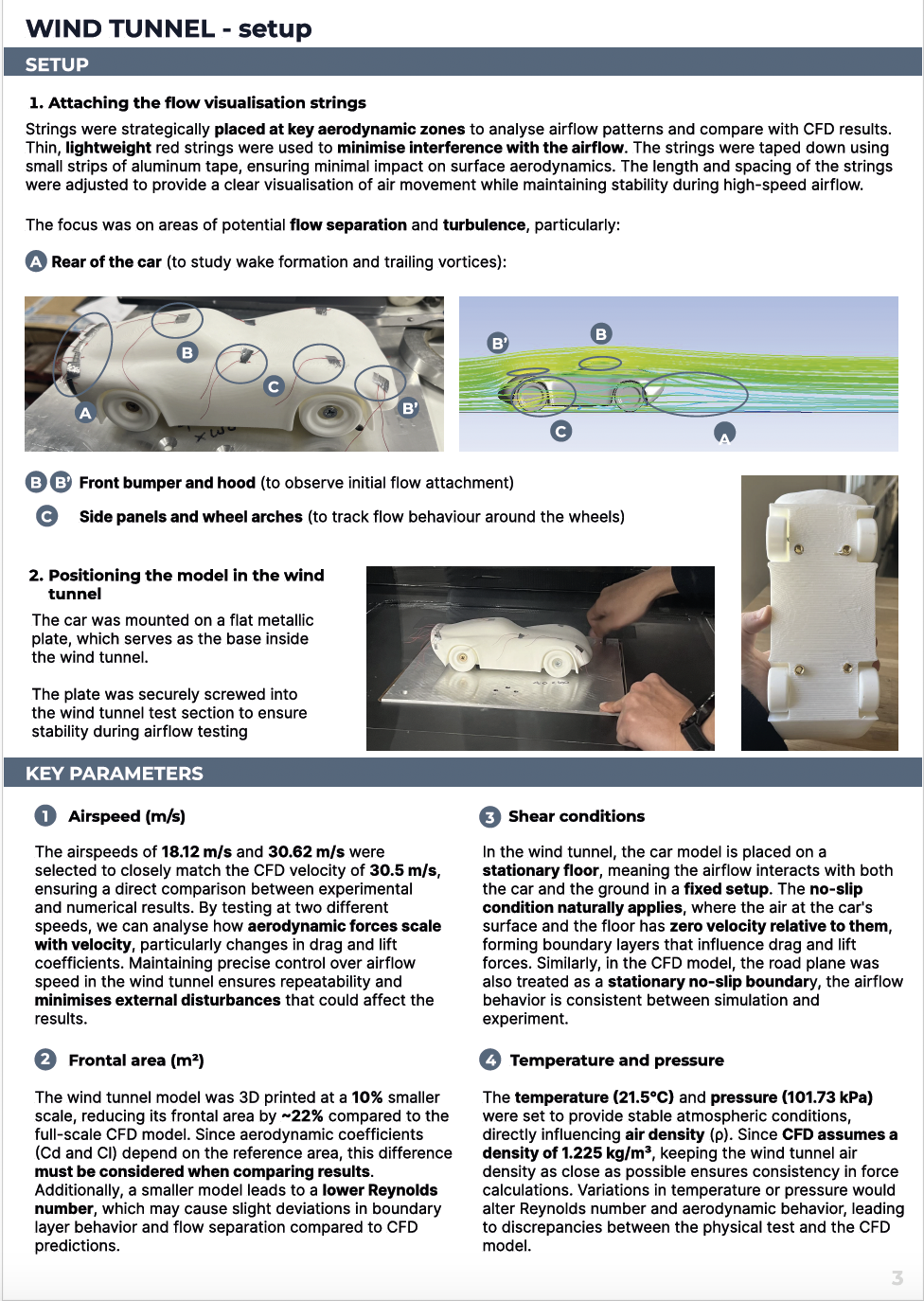

3D printed scale models tested in wind tunnel with flow visualisation and force measurements.

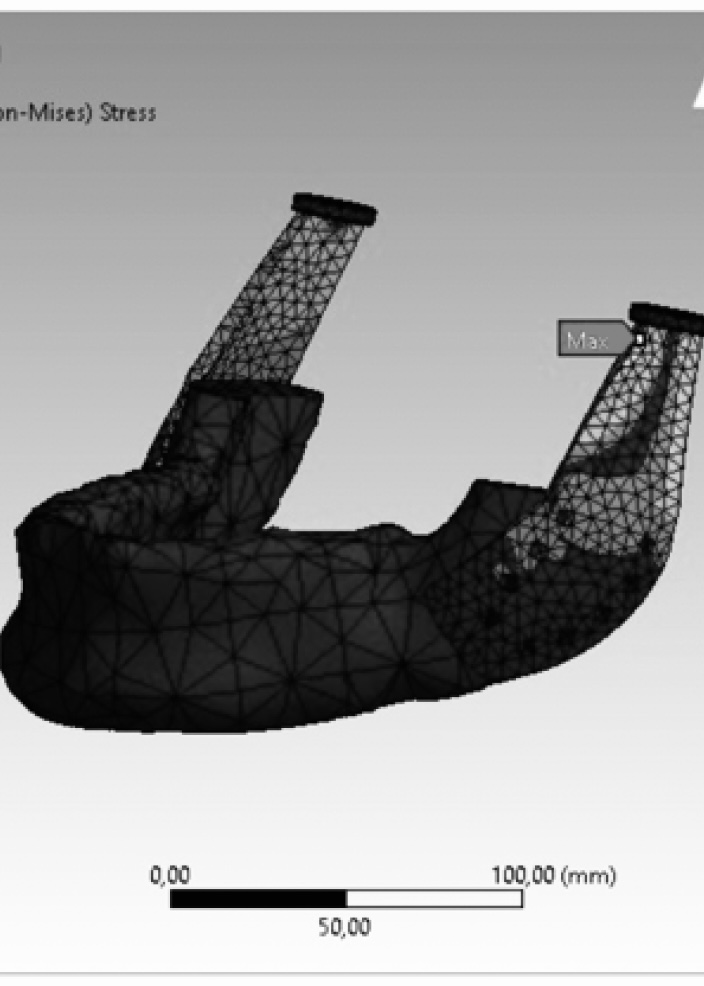

Thermal System

Copper pipeline cooling system with optimised flow velocity and high-conductivity cooling plates.

Key Results

- 25% drag coefficient reduction

- Eliminated flow separation zones

- Reduced lift-inducing effects

- Optimised thermal distribution

- Validated CFD predictions

- Minimised pressure drops

Engineering Process

Design Analysis

Initial assessment of Mercedes-Benz 300 SL aerodynamics, identifying flow separation and drag-inducing features.

CFD Optimisation

Iterative 3D modeling and ANSYS simulations to develop aerodynamic improvements and thermal systems.

Physical Testing

3D printed scale models tested in wind tunnel with comprehensive flow visualisation and force measurements.

Validation & Analysis

Comparing CFD predictions with experimental data, analszing scaling effects and Reynolds number dependencies.

Technical Report

These are selected excerpts from my technical reports to give a glimpse into the simulations and calculations performed; they don’t represent the full documentation.

Learning & Impact

This project sharpened my skills in fluid mechanics, simulation, physical testing, and design iteration; but more importantly, it taught me how to integrate digital and physical methods to engineer for performance, efficiency, and reliability.

Simulation Mastery

Advanced proficiency in CFD analysis using ANSYS Fluent for complex aerodynamic and thermal problems

Experimental Skills

Hands-on experience with wind tunnel testing, flow visualisation, and validation methodologies

Design Integration

Successfully bridged theoretical knowledge with practical engineering constraints and real-world applications

"This experience highlighted the critical importance of validating digital simulations with physical testing, revealing the nuanced differences between idealised models and real-world physics."