Redefining Biomechanics through Digital Simulation

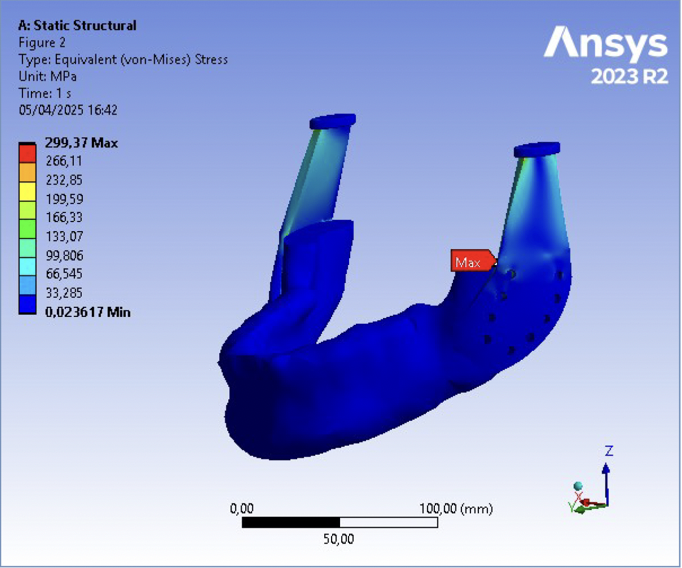

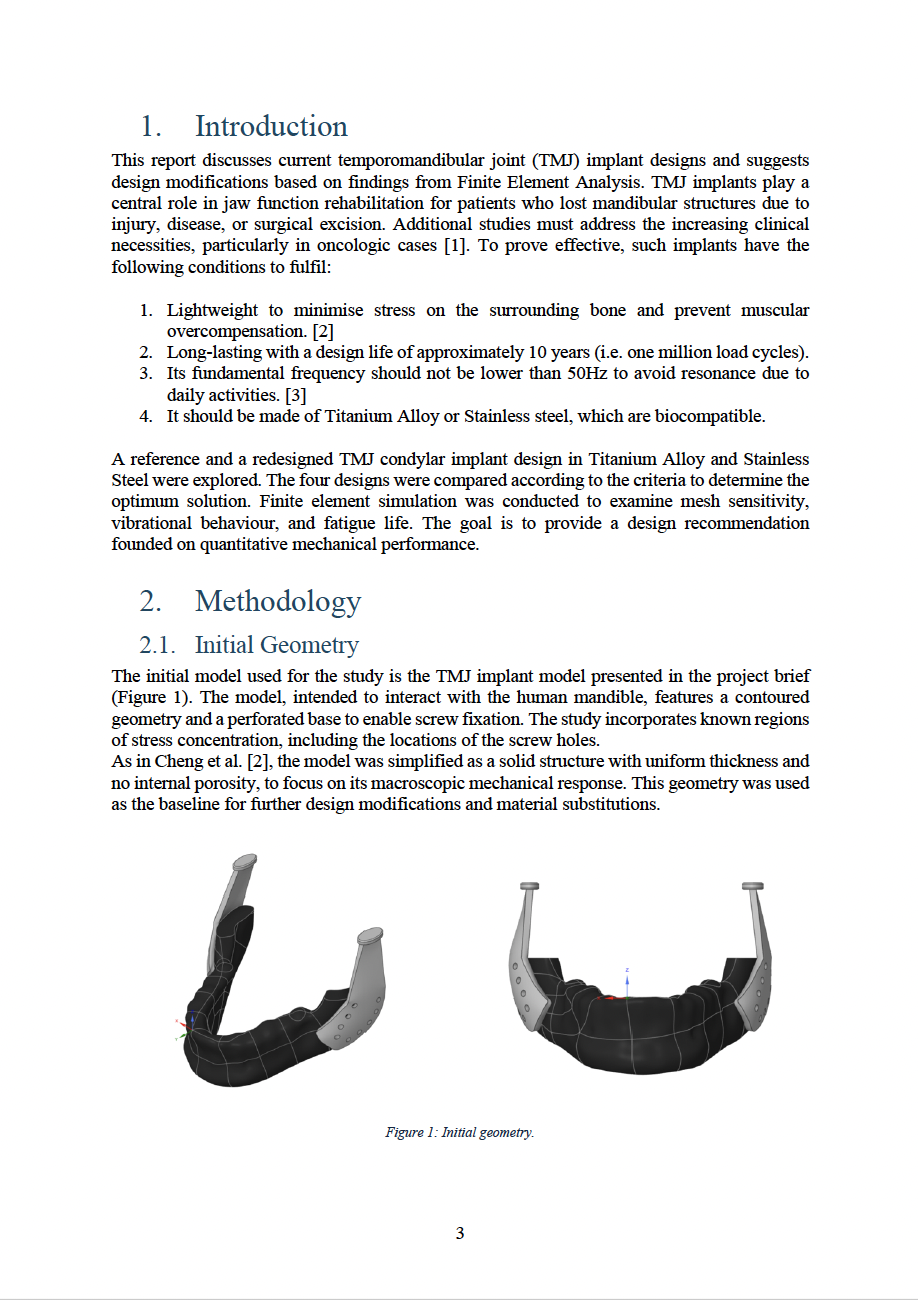

As part of the Finite Element Analysis module in second year, I undertook a comprehensive structural and fatigue analysis of a Temporomandibular Joint (TMJ) implant. This project investigated two implant designs in Titanium Alloy (Ti-6Al-4V) and Stainless Steel 316L, assessing their performance under physiological loading.

Engineering Challenges

Structural Fatigue Resistance

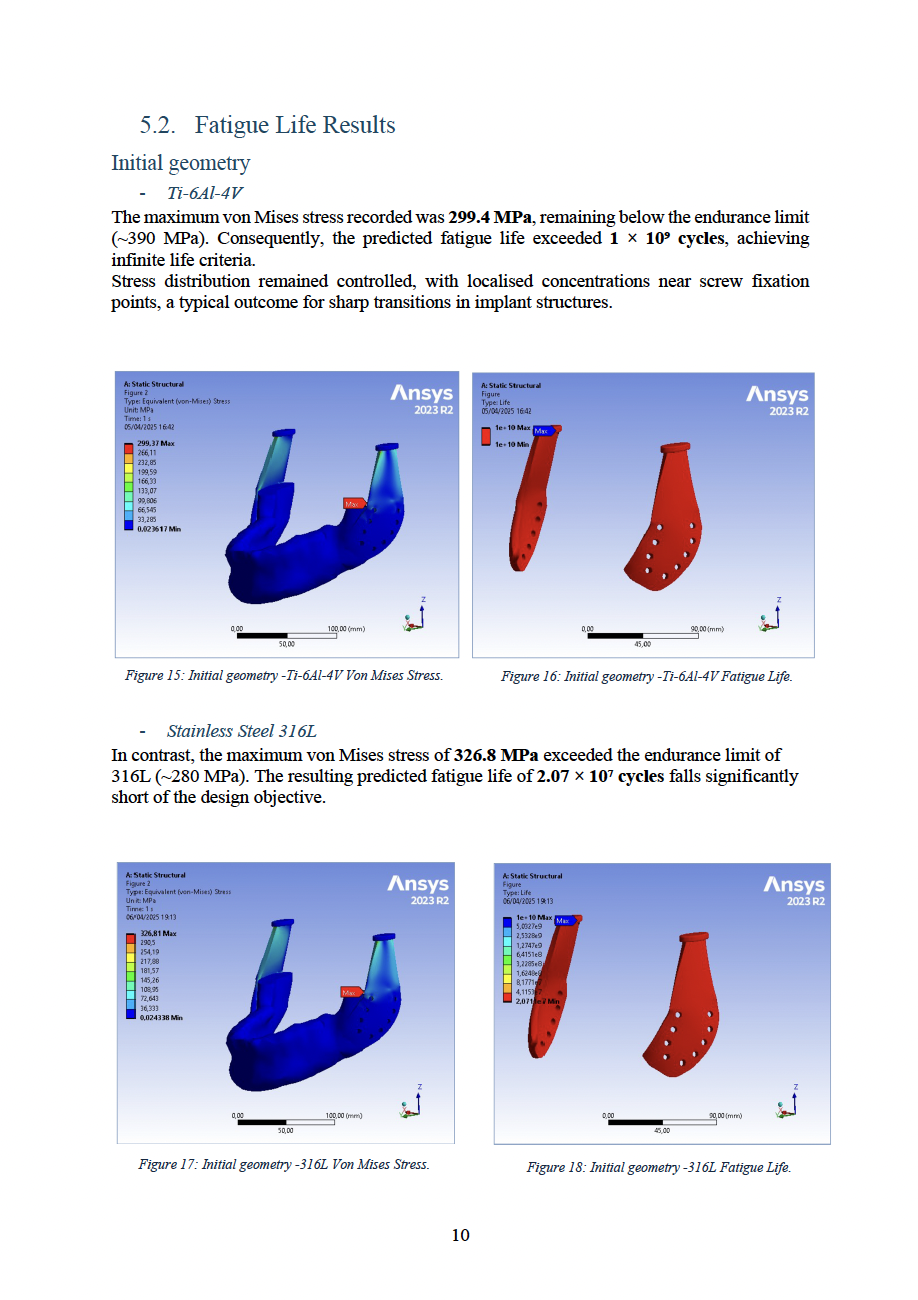

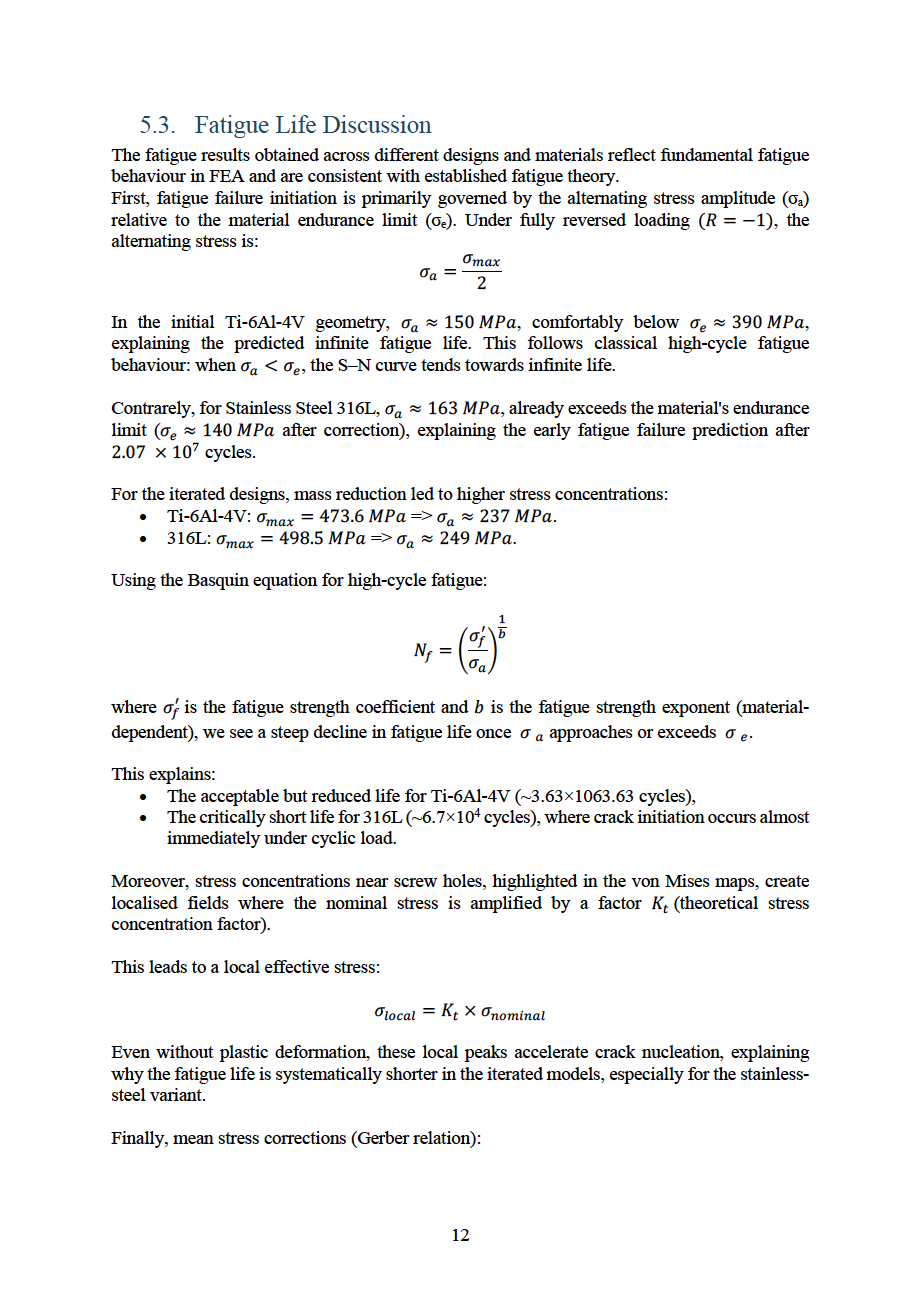

Simulating fully-reversed chewing loads (R = –1), the implant needed to survive >1 billion cycles. Titanium achieved infinite fatigue life in the baseline design, while Stainless Steel failed early due to lower endurance limits. Iterated designs faced critical stress concentrations.

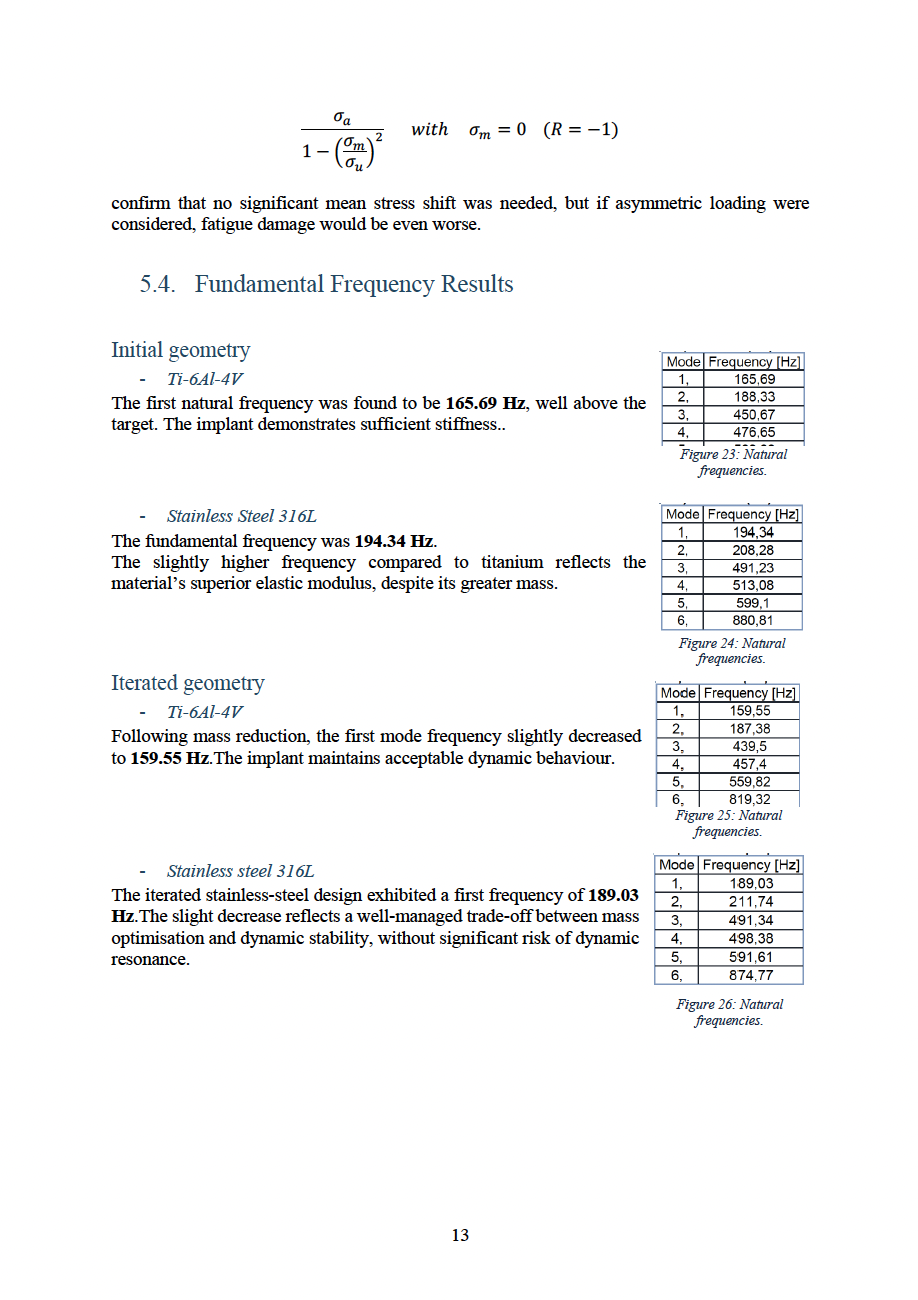

Vibrational Behaviour & Modal Analysis

To avoid resonance during daily activities like chewing or talking, the implant's first natural frequency had to exceed 50 Hz. All tested designs achieved this, with modal frequencies between 159–194 Hz, confirming safe dynamic performance.

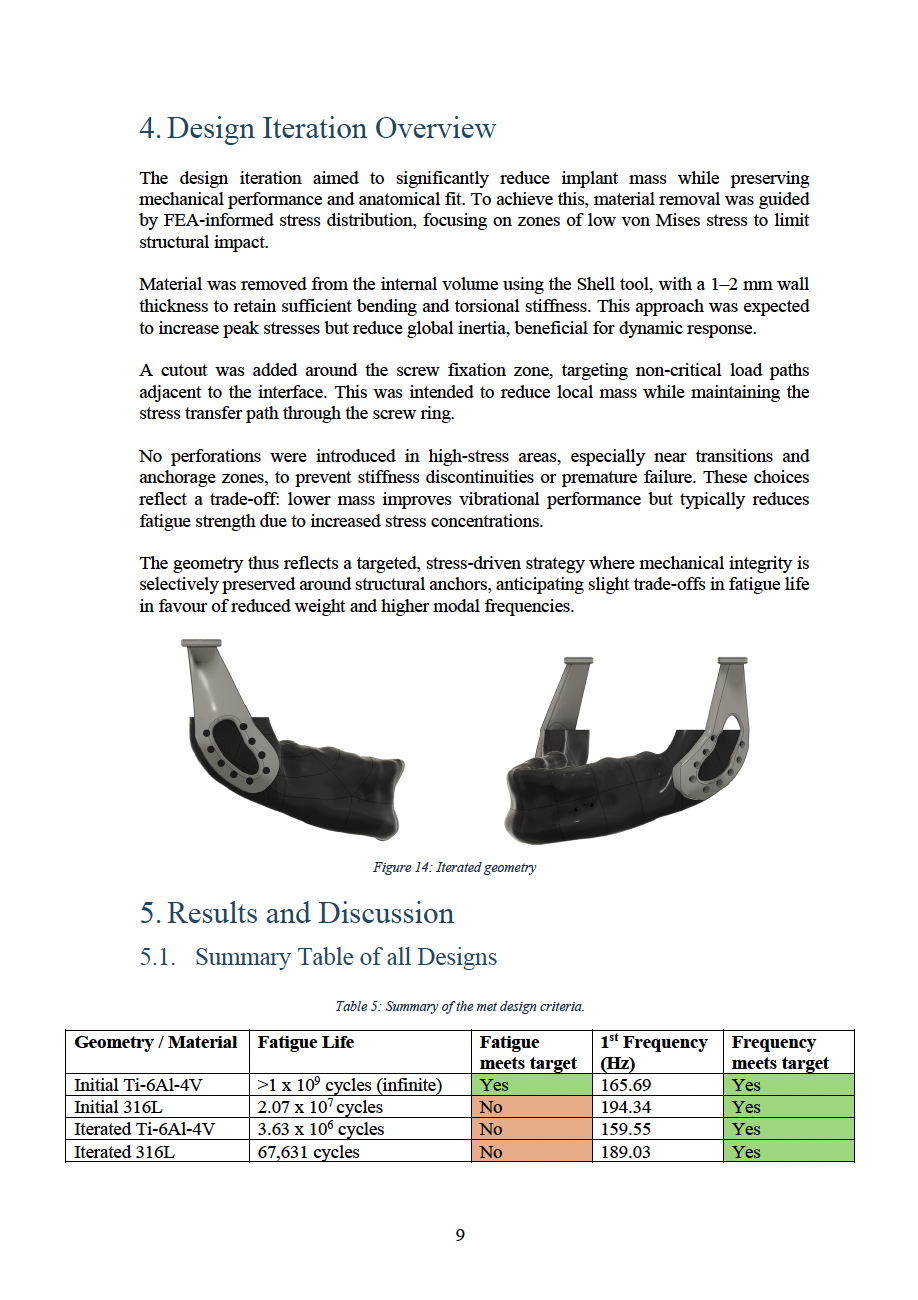

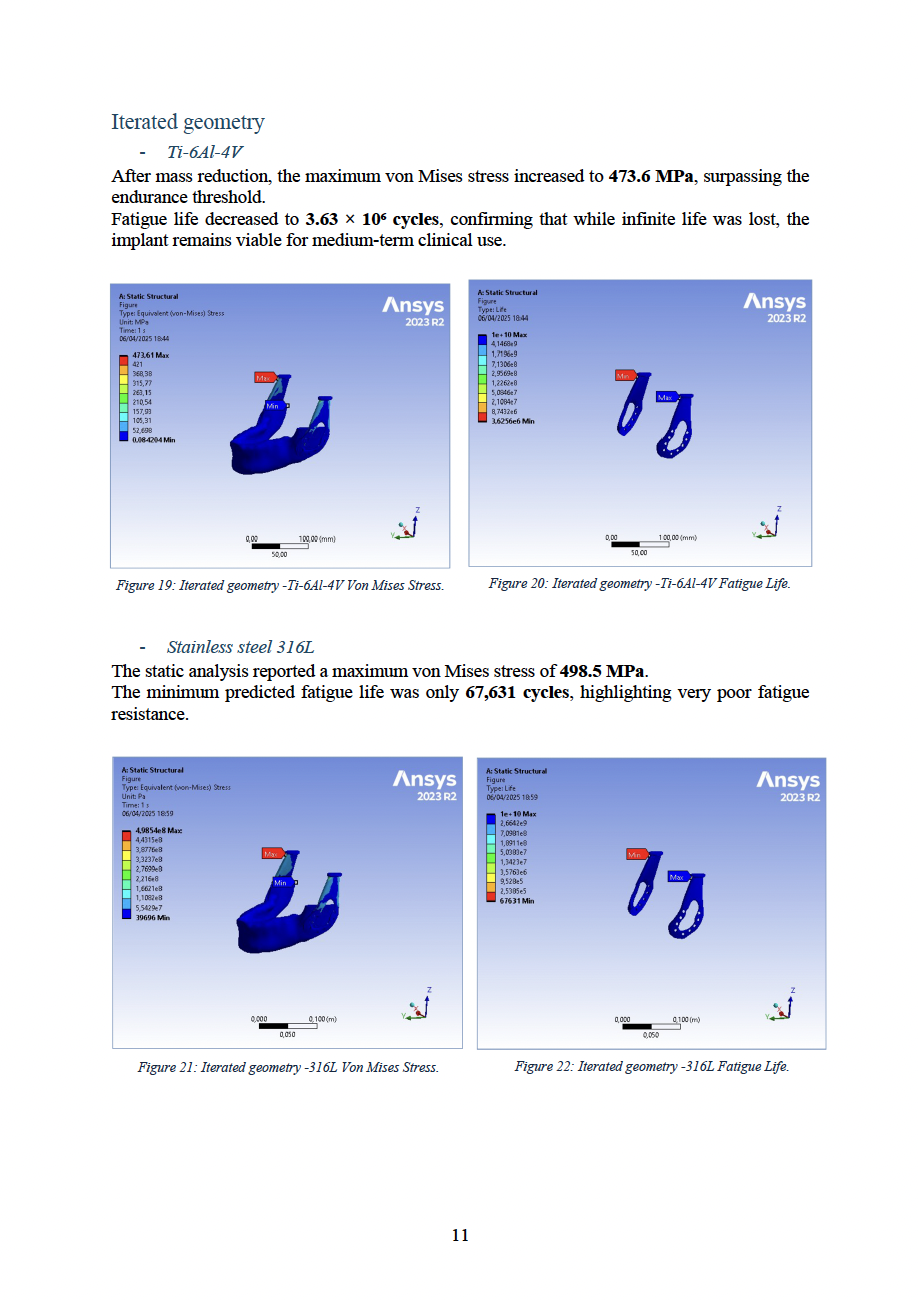

Mass Reduction vs. Integrity

A new implant geometry was developed by hollowing low-stress areas and trimming mass near screw fixation zones. This increased peak stresses but improved modal response. The design reflects a trade-off between mechanical strength and lightweight optimisation.

Engineering Solutions

Using iterative CAD modeling and Finite Element simulations in ANSYS, I explored material selection, structural performance, and fatigue behaviour. The goal was to create a biocompatible and lightweight TMJ implant that meets both mechanical and clinical standards.

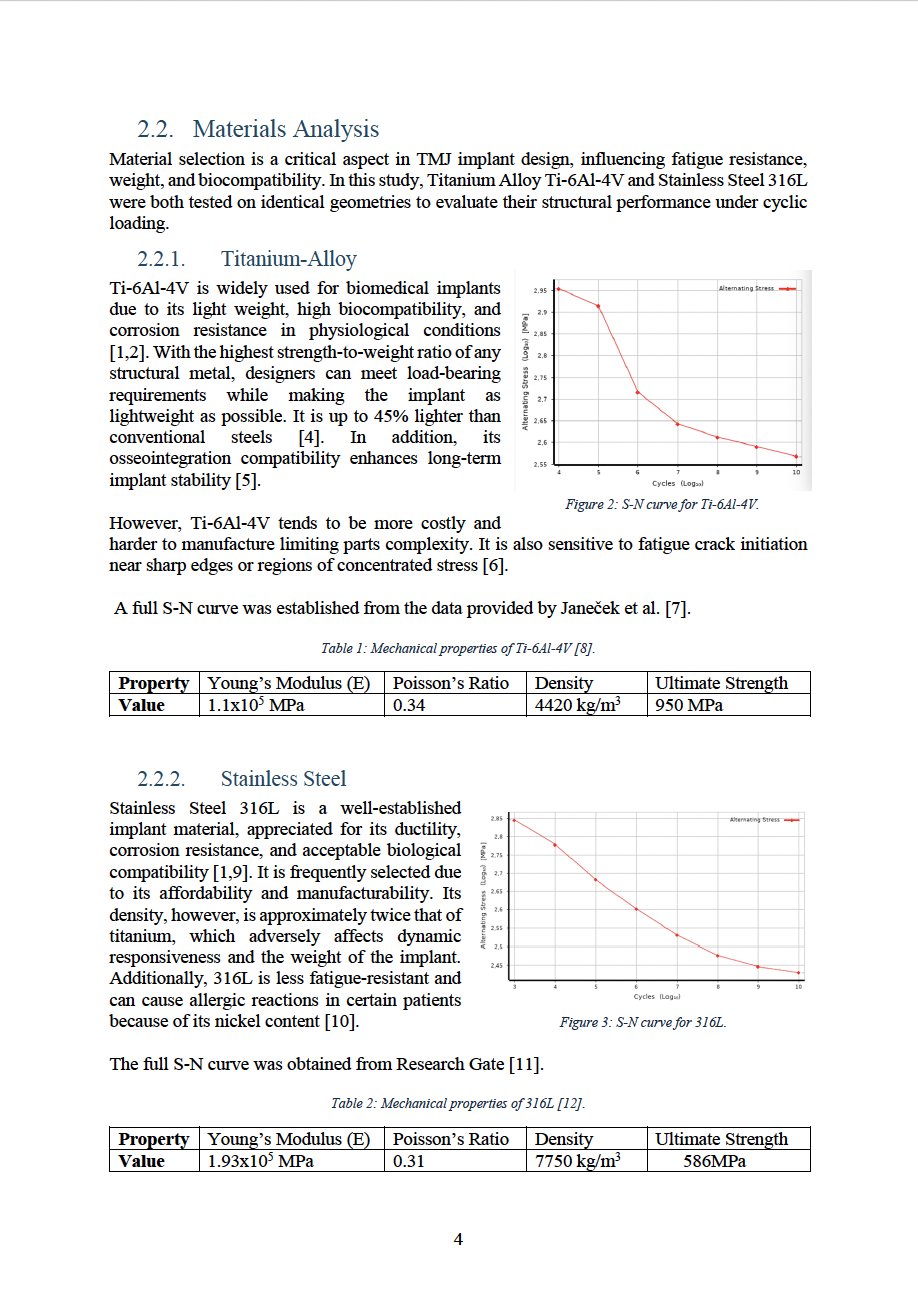

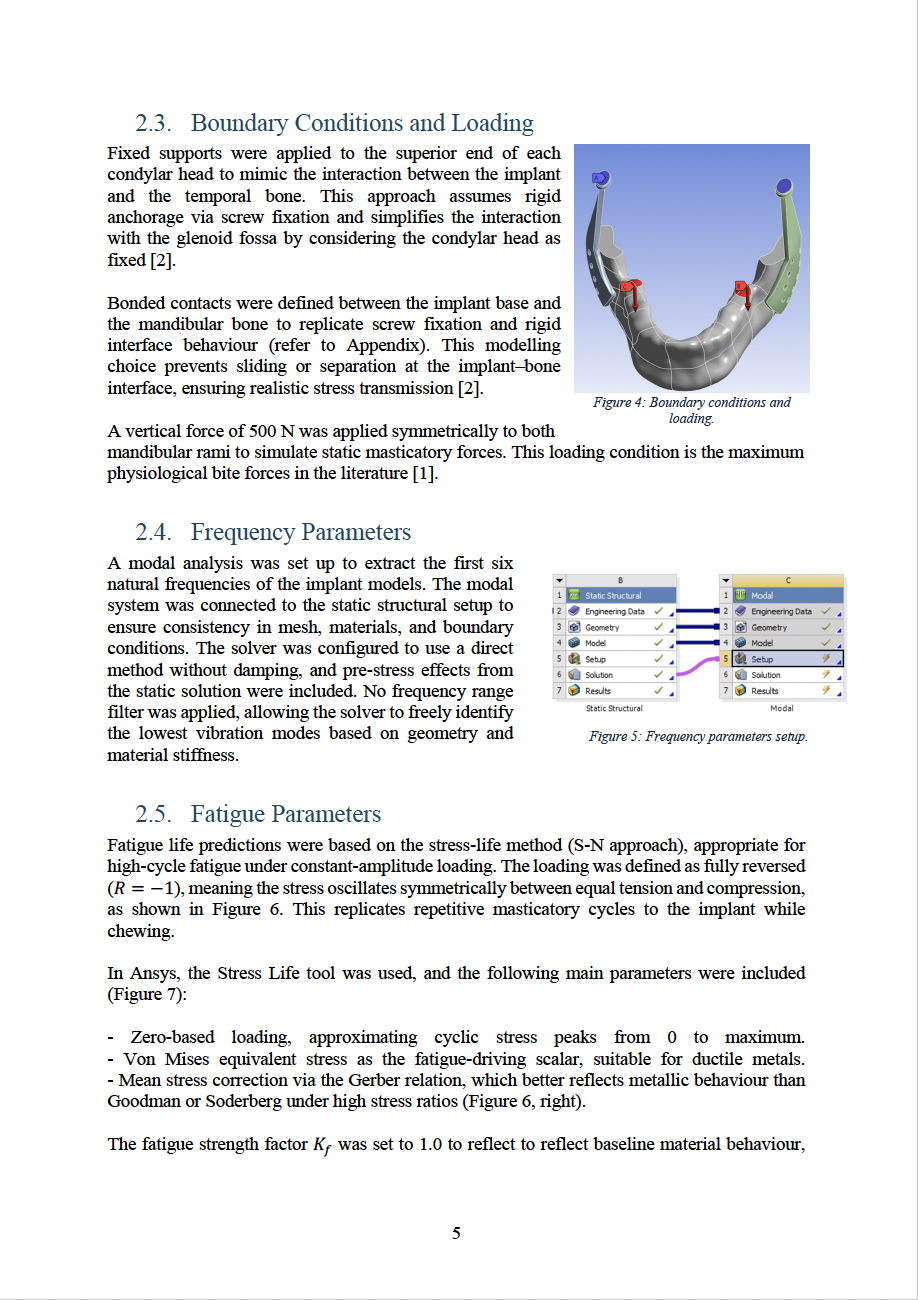

Material Selection

Compared Titanium Alloy (Ti-6Al-4V) and Stainless Steel 316L. Titanium offered superior fatigue life and reduced mass, while steel provided higher stiffness but failed under cyclic loading.

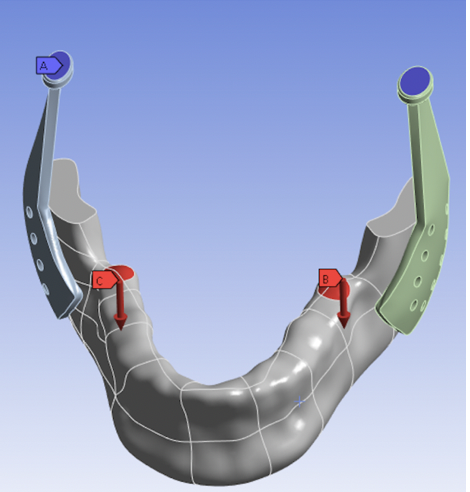

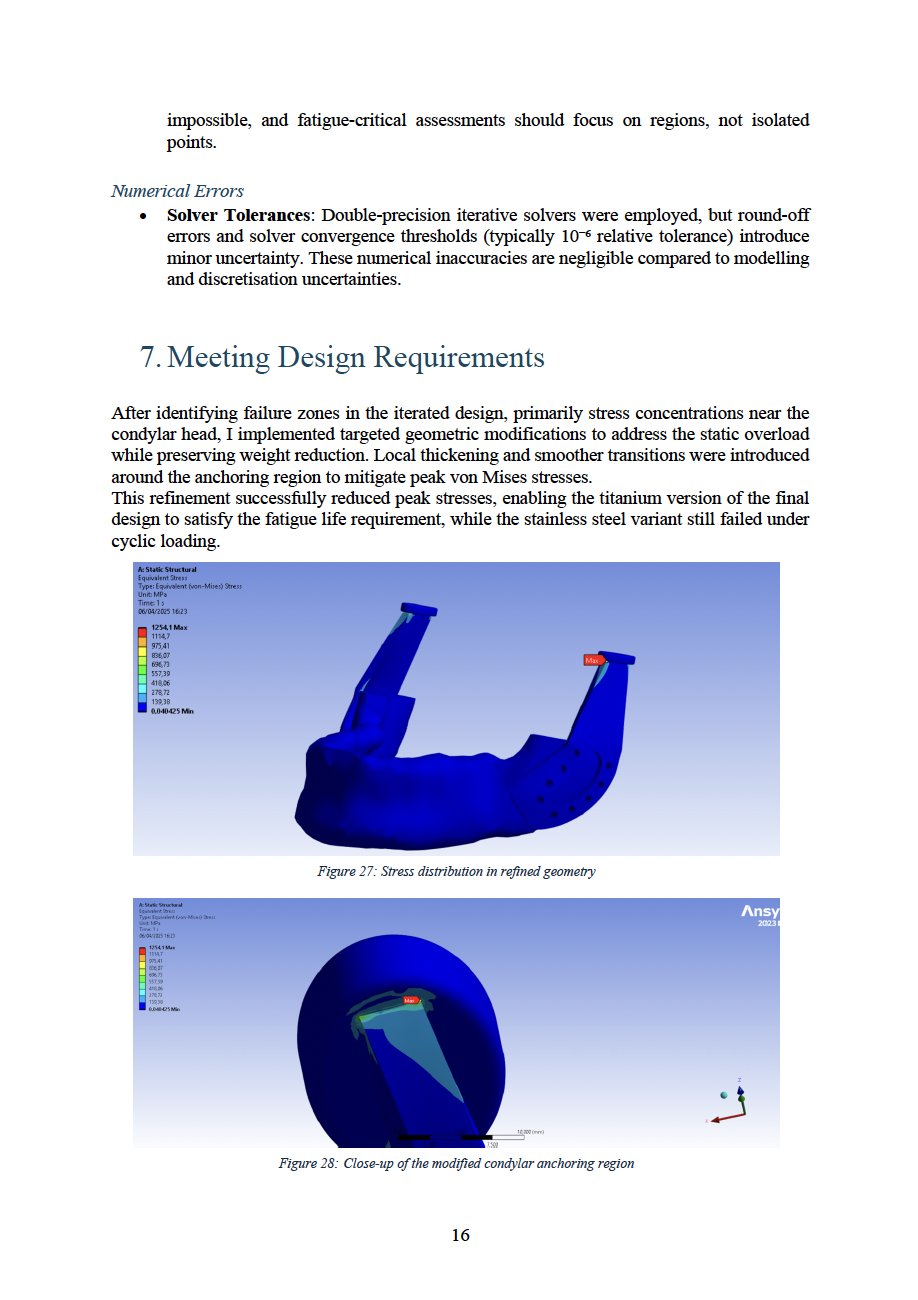

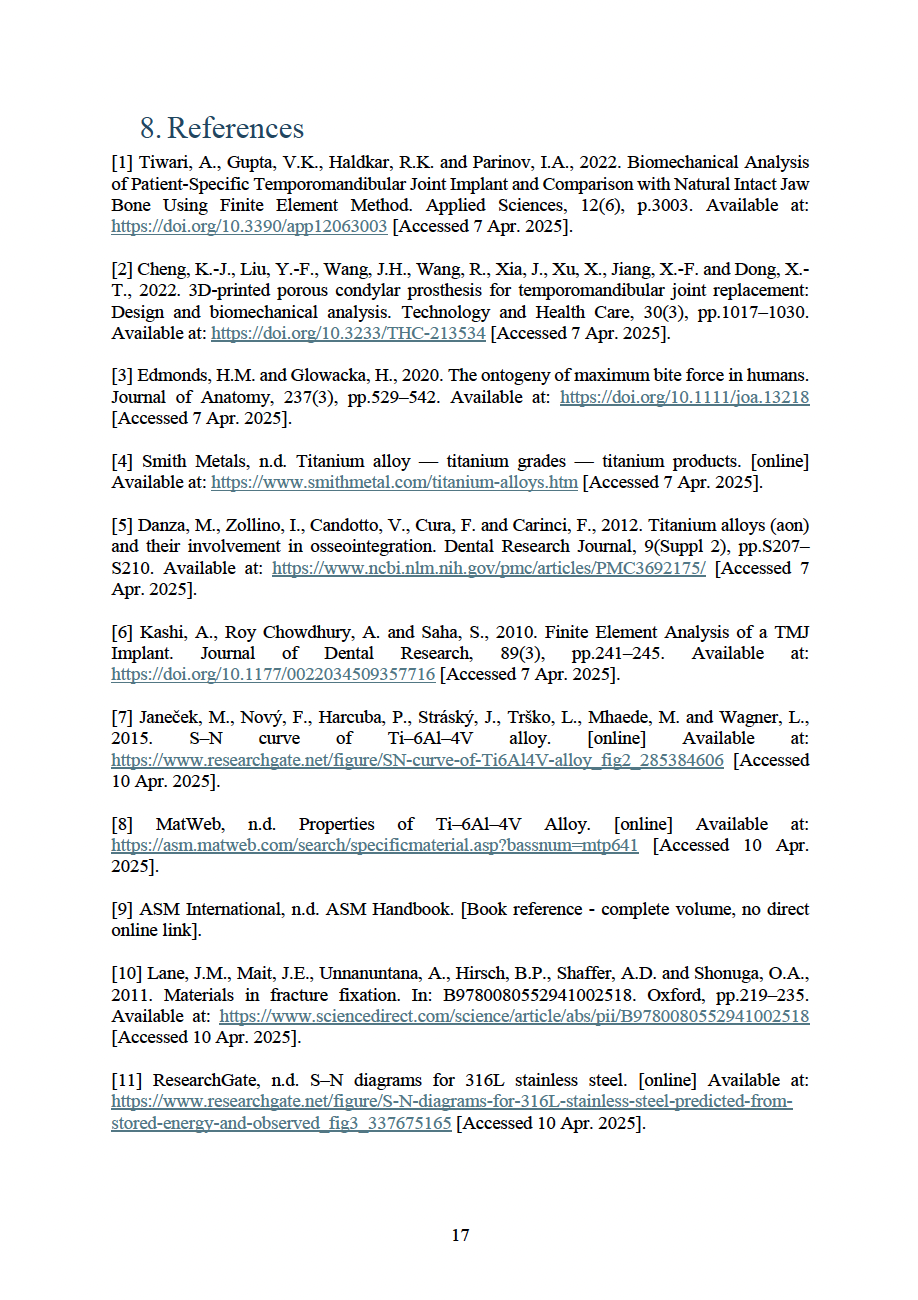

Stress-Guided Geometry Optimisation

Iterated design by hollowing low-stress zones using FEA data. Reduced implant mass by ~25%, maintaining integrity in high-load areas such as screw fixation regions.

Fatigue & Modal Simulations

Simulated fully-reversed loads (R = –1) to predict long-term fatigue life using S–N curves and Gerber correction. Modal analysis ensured first natural frequency >150 Hz for resonance safety.

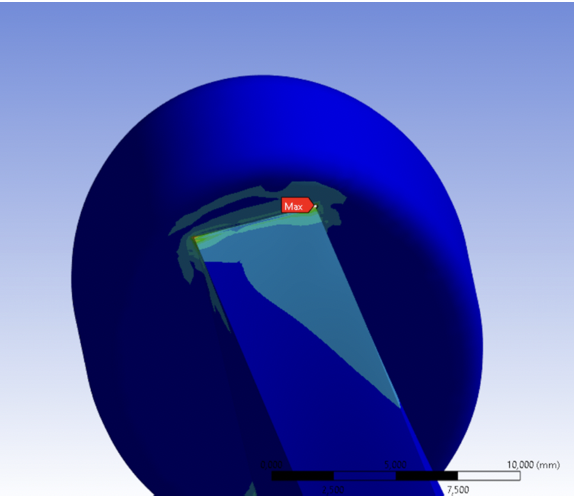

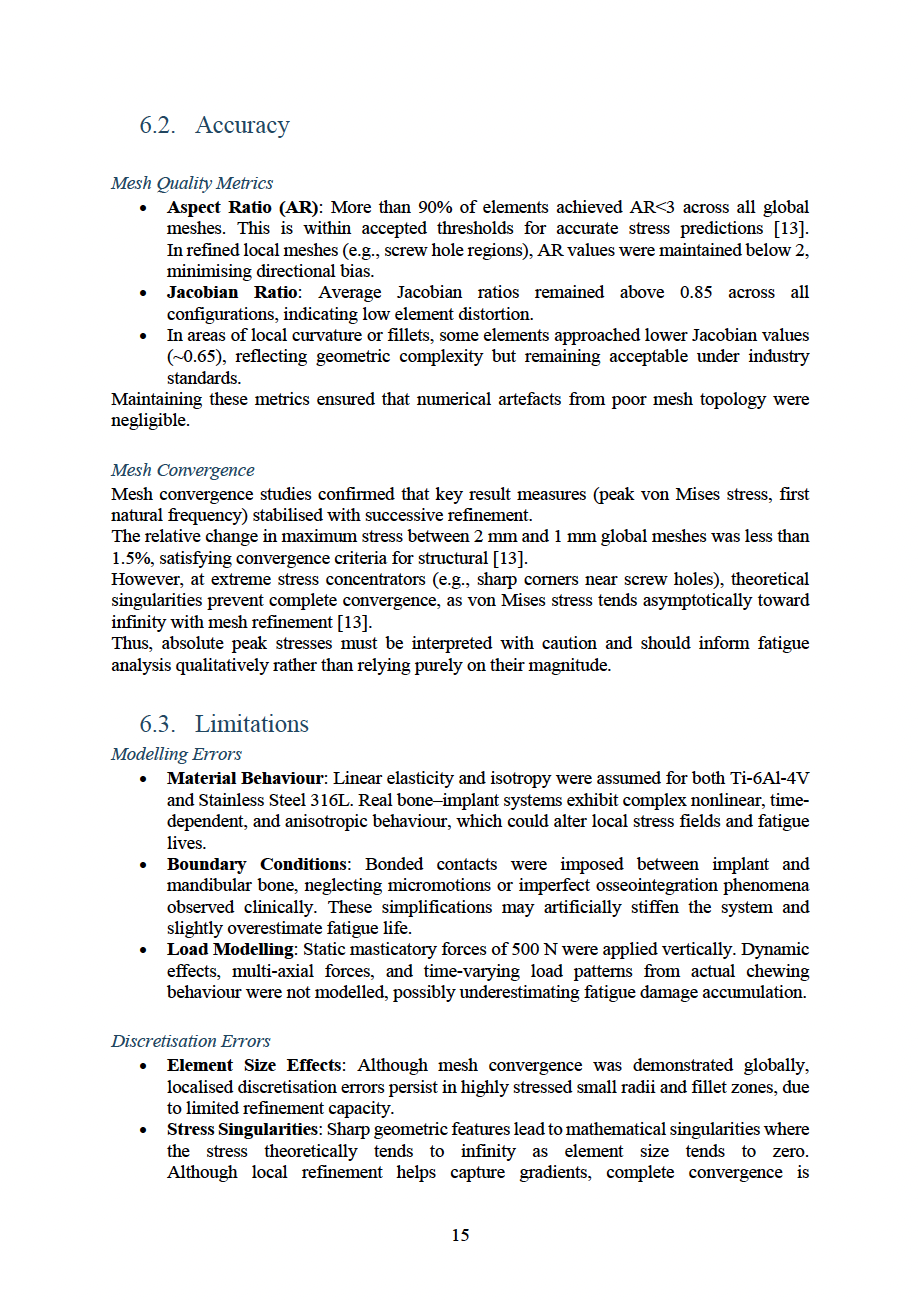

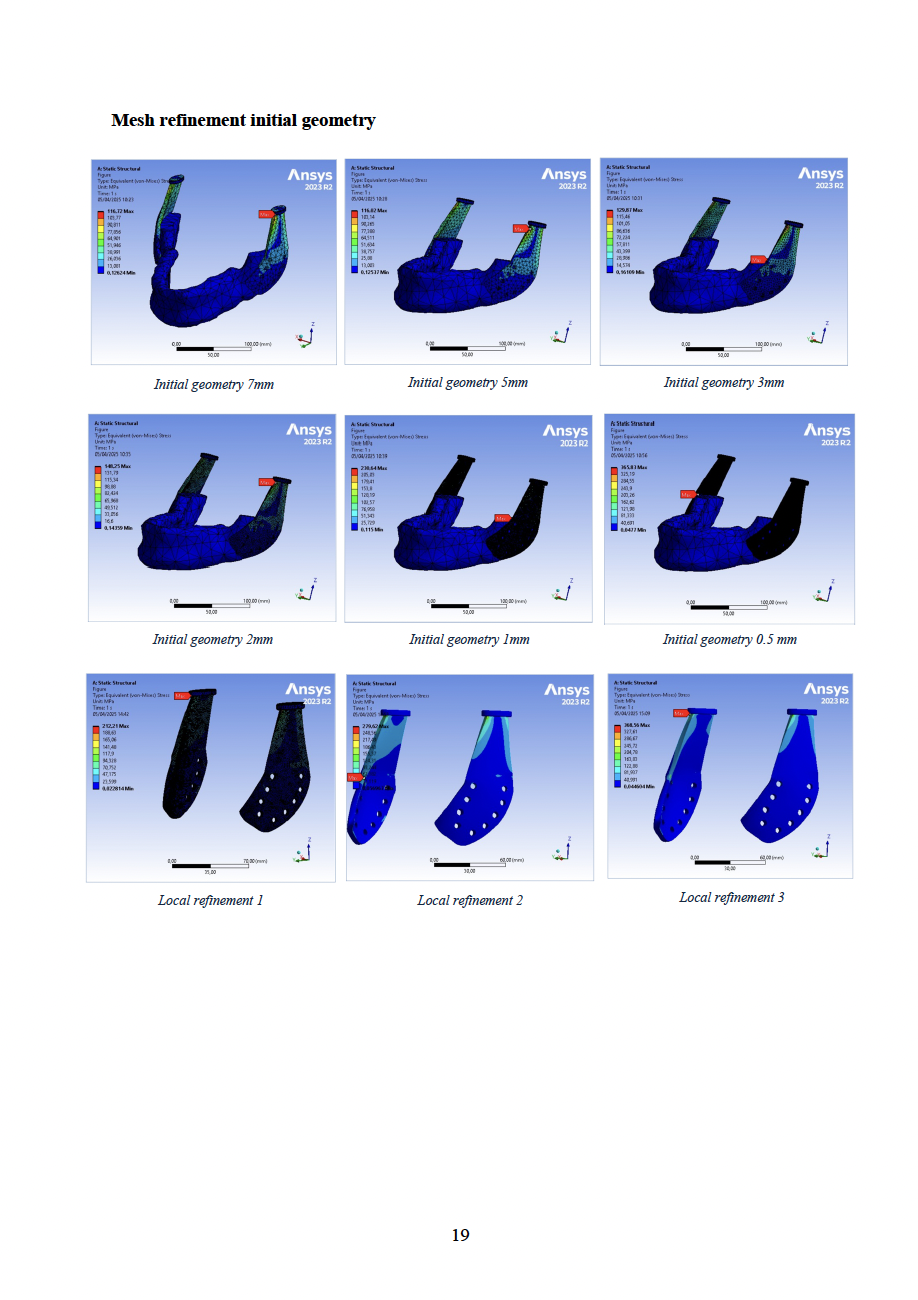

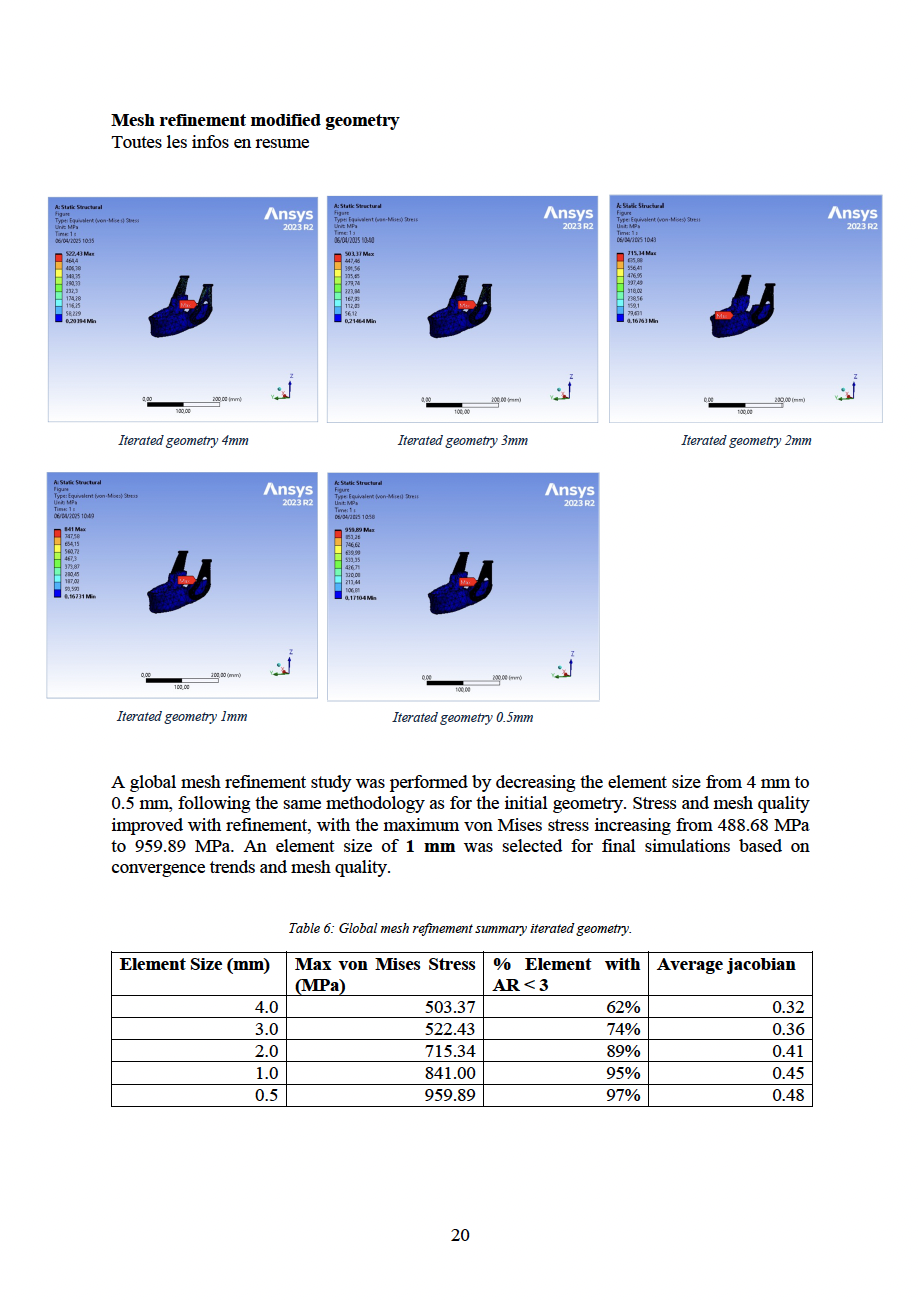

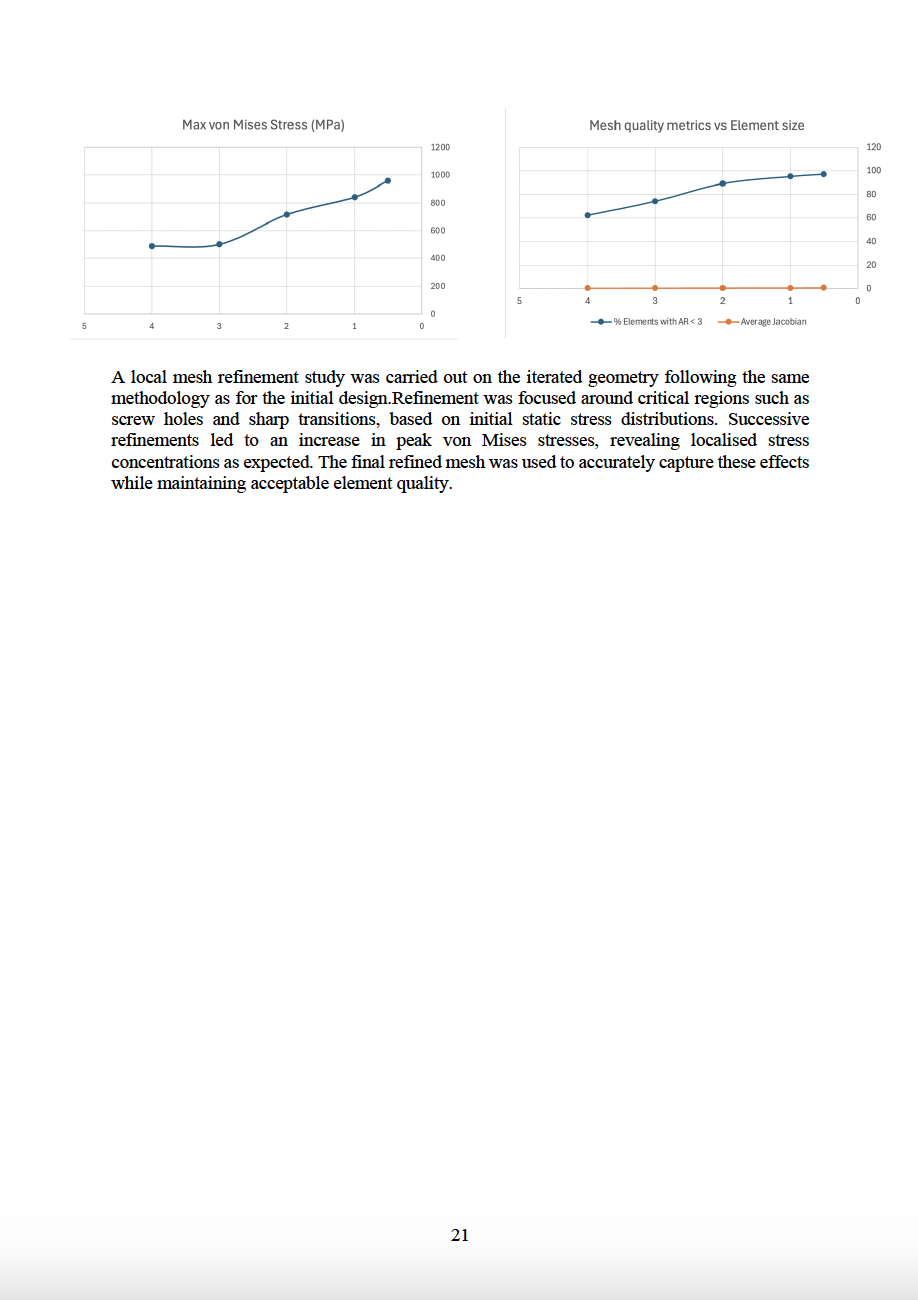

Mesh Refinement & Accuracy

Conducted global and local mesh studies. Achieved convergence in stress values and high element quality (AR < 3, Jacobian > 0.4) for reliable simulation results.

Key Results

- Infinite fatigue life achieved with initial Titanium design

- 3.63×10⁶ cycles on iterated Titanium version

- 25% mass reduction in modified geometry

- >150 Hz modal frequencies on all designs

- Mesh quality maintained: AR < 3 on 96% of elements

- Fatigue failure predicted in Stainless Steel due to high stress

Engineering Process

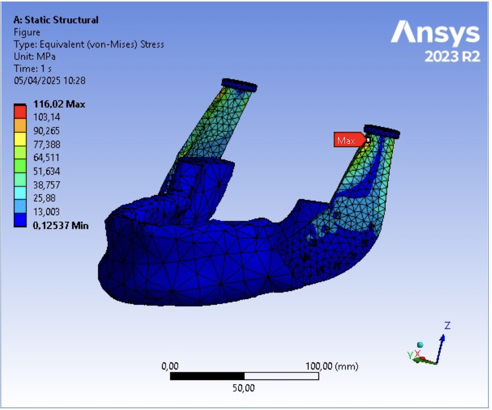

Geometry & Load Setup

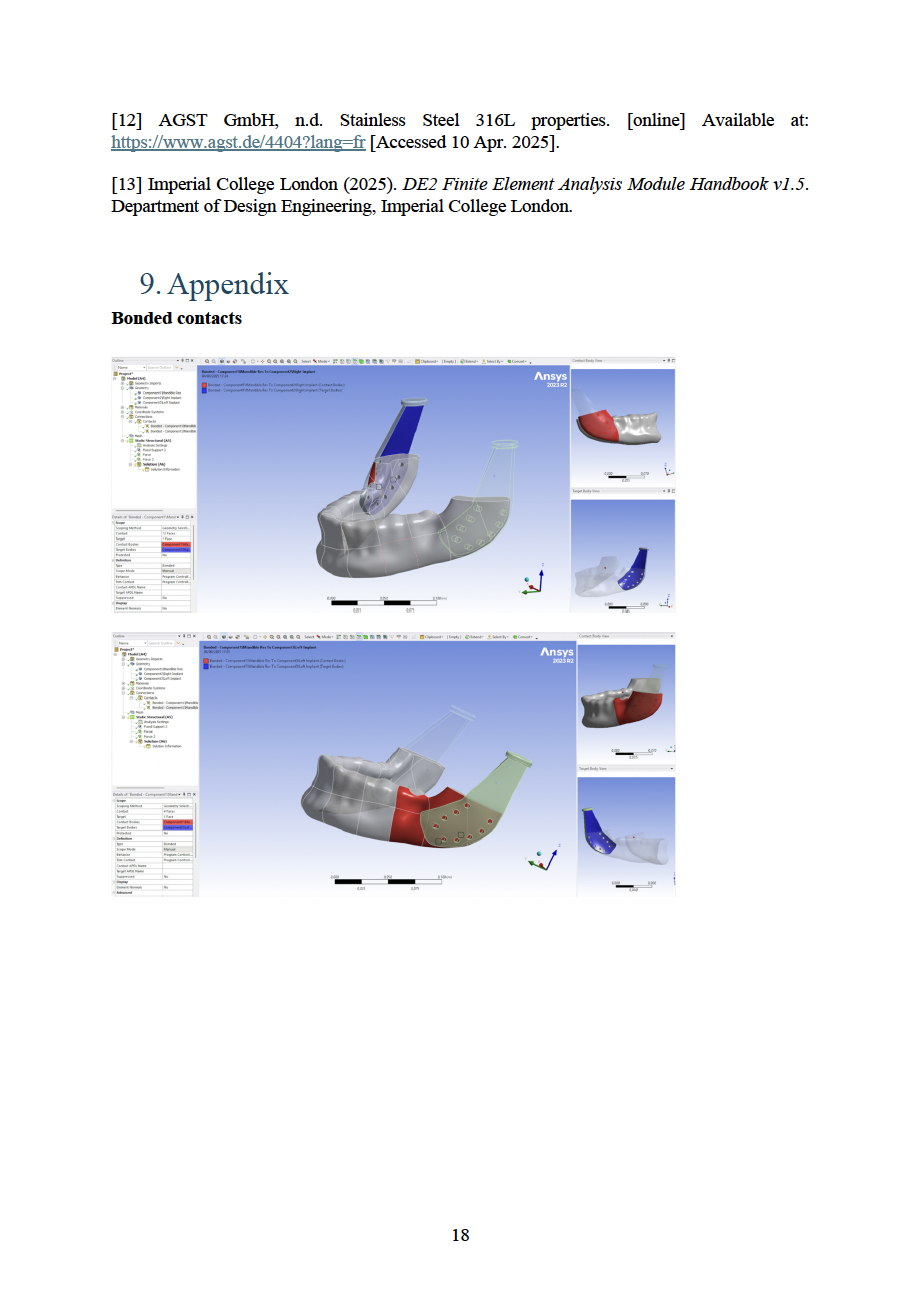

Imported TMJ CAD model. Defined screw fixation, physiological loads (500 N), and material properties (Titanium and 316L). Contacts bonded for accurate force transmission.

Mesh Convergence

Performed global and local refinement. Selected mesh sizes ensuring peak stress and modal stability, balancing accuracy and computation time.

Fatigue & Modal Simulations

Conducted fully-reversed fatigue simulations using Gerber correction. Modal analysis confirmed fundamental frequencies safely above resonance threshold.

Design Iteration & Final Evaluation

Mass was removed from low-stress zones. Final design balanced stiffness and lightweight goals. Titanium met most clinical requirements; stainless steel did not.

Technical Report

These are selected excerpts from my technical reports to give a glimpse into the simulations and calculations performed; they don’t represent the full documentation.

Learning & Impact

This project deepened my understanding of biomechanics, fatigue theory, and simulation accuracy. Beyond technical proficiency, it taught me how to make informed engineering decisions—balancing performance, manufacturability, and clinical feasibility.

Simulation Expertise

Developed advanced proficiency in ANSYS Workbench, applying mesh convergence studies, fatigue predictions, and modal analysis to biomedical implants.

Engineering Judgment

Learned to interpret FEA results critically, identify failure-prone regions, and implement geometry changes to meet fatigue life targets under physiological loads.

Design for Performance

Integrated stress-based modelling with medical requirements, achieving a trade-off between mass reduction, fatigue resistance, and vibrational stability.

"This project taught me the importance of aligning digital simulation with real-world mechanical limits. It revealed that even the most elegant model must answer to fatigue, vibration, and manufacturability."